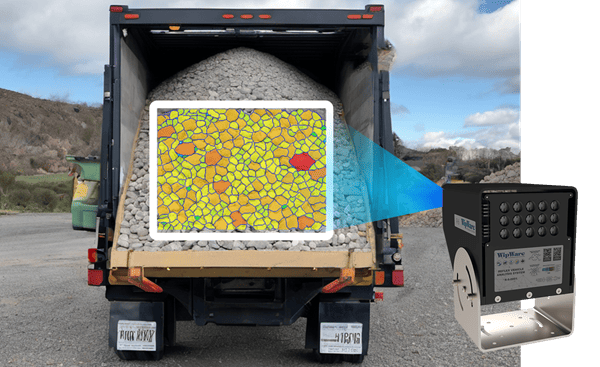

反射™ 6 Vehicle Analysis System focuses on acquiring high quality images that are processed onboard providing real-time telemetry to your control system, data historian or automatic daily reporting.

准确捕捉快速移动

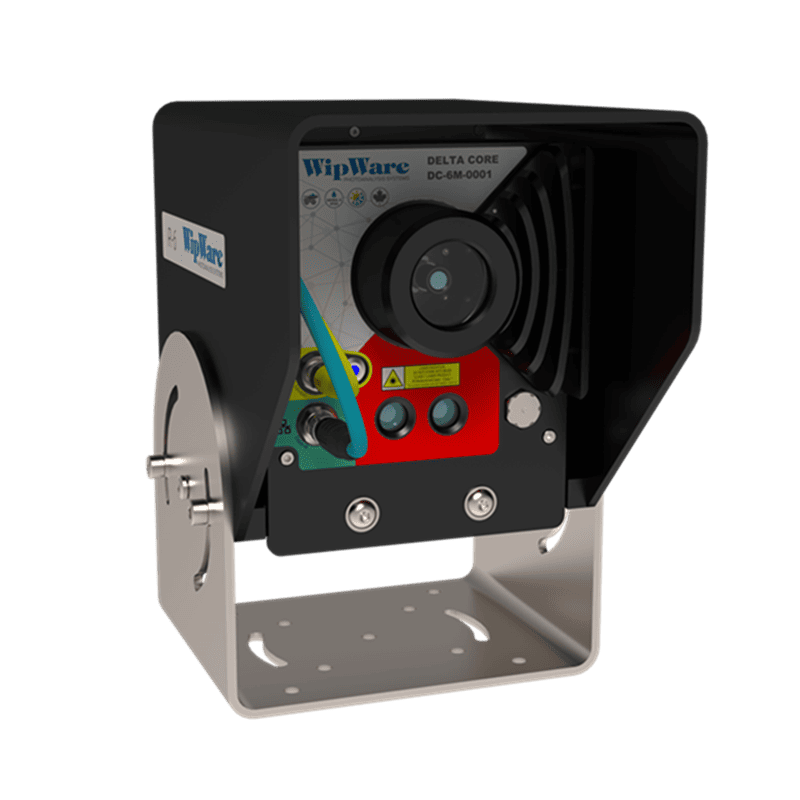

设计用于在主破碎机上移动HD,LHD和铁路车辆时使用,而不会中断生产。它具有激光触发功能,可以在捕获图像之前感应卡车的位置。

Reflex 6 Features

- 完全自主,运营24-7

- 适用于工业环境的坚固的多合一设计(工作于-40°C至+ 80°C)

- Performs well in harsh conditons

- 快速部署,可从任何地方远程访问

- 爆炸优化

- 使用WipFrag作为HMI。无需许可证

- 与现有过程控制系统(Modbus TCP,OPC UA)通信

可用型号

反射 6 基本的

达到最大粒径或检测主破碎机的颜色差异。

- 初级破碎机超大尺寸检测

- 污染/稀释检测

Reflex 6 Basic can be upgraded to Reflex 6 Complete unlocking additional features

随时与 无需更改硬件。

反射 6 Complete

Designed to measure particle size, shape and colour differentiation at the primary crusher. Includes Basic features plus:

- 实时碎片遥测

- 25种用户定义的尺寸

- 量化爆炸性能

- 改善物料处理

- 优化破碎机产量

- 高度可配置

跨多个平台随时随地查看结果

可以通过台式计算机远程访问结果,也可以使用iOS或Android设备触手可及。

板载彩色摄像机能够将信号发送到警报/ PLC /事件过程。

Customer Testimonials

Automated fragmentation – drill and blast performance

Automated fragmentation photo analysis is being used at Lafarge, Ravena quarry as a part of our ongoing drill, blast and primary crushing continuous process. WipWare’s Reflex system at the Lafarge quarry has been found to be a useful tool for monitoring and collecting raw data that is utilized to evaluate drill/blast performance. One of the examples of the measured gains achieved there using WipWare’s Reflex system as a blast/crush improvement toll is a 20% increase in crusher productivity and 12% reduction in crushed product cost with no change in drill and blast cost.