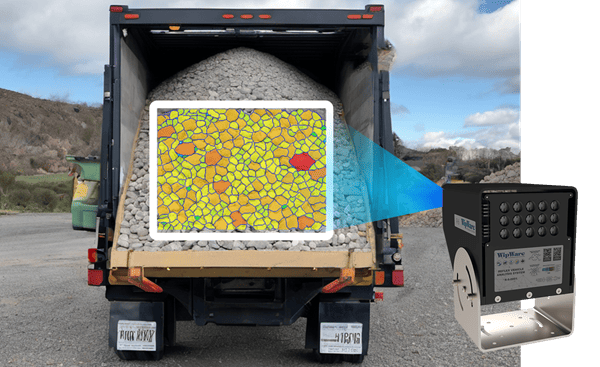

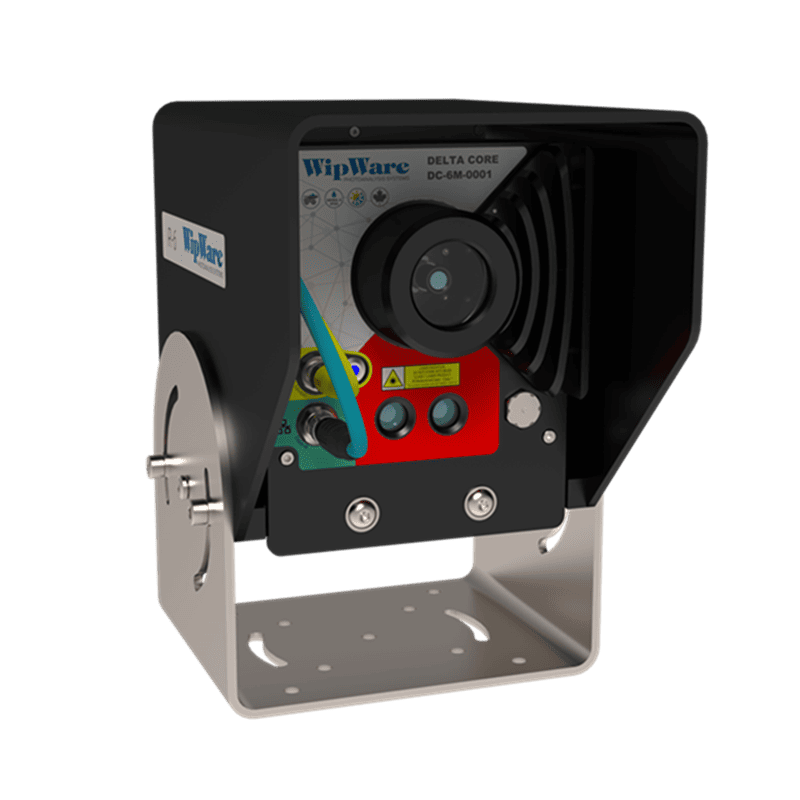

Réflexe™ 6 Vehicle Analysis System focuses on acquiring high quality images that are processed onboard providing real-time telemetry to your control system, data historian or automatic daily reporting.

Capturez les mouvements rapides avec précision

Conçu pour être utilisé sur les véhicules HD, LHD et wagons mobiles au niveau du concasseur primaire sans perturber la production Il dispose de capacités de déclenchement laser pour détecter l'emplacement du camion avant de capturer des images.

Reflex 6 Features

- Complètement autonome, fonctionne 24h / 24 et 7j / 7

- Conception robuste tout-en-un pour les environnements industriels (fonctionne de -40 ° C à + 80 ° C)

- Performs well in harsh conditons

- Déploiement rapide, accessible à distance de n'importe où

- Optimisation des explosions

- Utilise WipFrag comme IHM. Aucune licence requise

- Communique avec les systèmes de contrôle de processus existants (Modbus TCP, OPC UA)

Modèles disponibles

Réflexe 6 De base

Cible la taille maximale des particules ou détecte la différenciation des couleurs au niveau du concasseur principal.

- Détection de surdimensionnement du concasseur pré-primaire

- Détection de contamination / dilution

Le Reflex 6 Basic can be upgraded to Reflex 6 Complete unlocking additional features

à tout moment avec aucune modification matérielle requise.

Réflexe 6 Complete

Designed to measure particle size, shape and colour differentiation at the primary crusher. Includes Basic features plus:

- Télémétrie de fragmentation en temps réel

- 25 tailles définies par l'utilisateur

- Quantifier les performances de souffle

- Améliorer la manutention des matériaux

- Optimiser le débit du concasseur

- Hautement configurable

Passez en revue les résultats n'importe où sur plusieurs plates-formes

Les résultats sont accessibles à distance via un ordinateur de bureau ou à portée de main avec un appareil iOS ou Android.

La caméra couleur intégrée a la capacité d'envoyer des signaux à un processus d'alarme / API / événement.

Customer Testimonials

Automated fragmentation – drill and blast performance

Automated fragmentation photo analysis is being used at Lafarge, Ravena quarry as a part of our ongoing drill, blast and primary crushing continuous process. WipWare’s Reflex system at the Lafarge quarry has been found to be a useful tool for monitoring and collecting raw data that is utilized to evaluate drill/blast performance. One of the examples of the measured gains achieved there using WipWare’s Reflex system as a blast/crush improvement toll is a 20% increase in crusher productivity and 12% reduction in crushed product cost with no change in drill and blast cost.