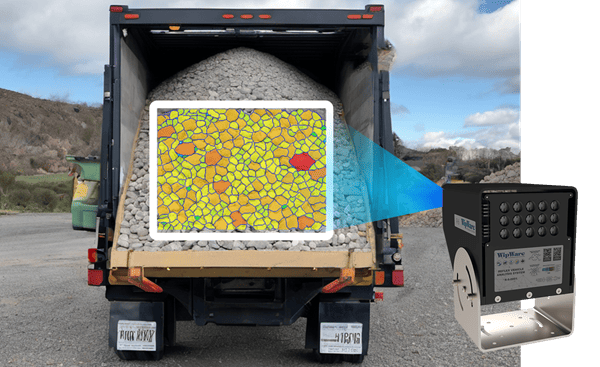

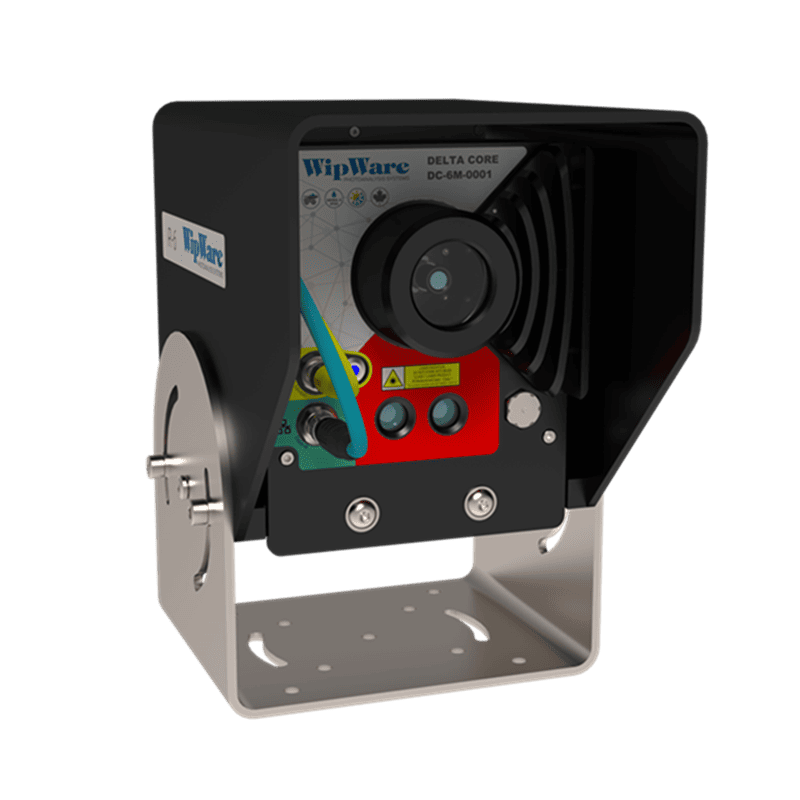

Reflejo™ 6 Vehicle Analysis System focuses on acquiring high quality images that are processed onboard providing real-time telemetry to your control system, data historian or automatic daily reporting.

Capture movimientos rápidos con precisión

Diseñado para usar en vehículos HD, LHD y automotores en movimiento en la trituradora primaria sin interrumpir la producción. Tiene capacidades de activación por láser para detectar la ubicación del camión antes de capturar imágenes.

Reflex 6 Features

- Completamente autónomo, Opera 24-7

- Diseño robusto todo en uno para entornos industriales (funciona de -40 °C a +80 °C)

- Performs well in harsh conditons

- Implementación rápida, acceso remoto desde cualquier lugar

- Optimización de voladuras

- Utiliza WipFrag como HMI. No se requiere licencia

- Se comunica con los sistemas de control de procesos existentes (Modbus TCP, OPC UA)

Modelos disponibles

Reflejo 6 Básico

Apunta al tamaño máximo de partícula o detecta la diferenciación de color en la trituradora primaria.

- Detección de sobredimensionamiento de la trituradora preprimaria

- Detección de contaminación/dilución

El reflejo 6 básico can be upgraded to Reflex 6 Complete unlocking additional features

en cualquier momento con no se requieren cambios de hardware.

Reflejo 6 Complete

Designed to measure particle size, shape and colour differentiation at the primary crusher. Includes Basic features plus:

- Telemetría de fragmentación en tiempo real

- 25 tamaños definidos por el usuario

- Cuantificar el rendimiento de las voladuras

- Mejorar el manejo de materiales

- Optimice el rendimiento de la trituradora

- Altamente configurable

Revise los resultados en cualquier lugar a través de múltiples plataformas

Se puede acceder a los resultados de forma remota a través de una computadora de escritorio o al alcance de su mano con un dispositivo iOS o Android.

La cámara a color integrada tiene la capacidad de enviar señales a un proceso de alarma/PLC/evento.

Customer Testimonials

Automated fragmentation – drill and blast performance

Automated fragmentation photo analysis is being used at Lafarge, Ravena quarry as a part of our ongoing drill, blast and primary crushing continuous process. WipWare’s Reflex system at the Lafarge quarry has been found to be a useful tool for monitoring and collecting raw data that is utilized to evaluate drill/blast performance. One of the examples of the measured gains achieved there using WipWare’s Reflex system as a blast/crush improvement toll is a 20% increase in crusher productivity and 12% reduction in crushed product cost with no change in drill and blast cost.