Solo™ 6 Conveyor Analysis System analyzes material on conveyor belts in real-time to automate your process, establish quality control, and improve safety, efficiency and throughput without disrupting production.

Capture movimientos rápidos con precisión

Permite una gestión remota eficaz con datos procesables y puede reducir drásticamente el mantenimiento, el tiempo de inactividad y el consumo de energía.

Eventos condicionales

Capacidad de enviar señales a un proceso de alarma/PLC/evento.

Muestreo instantáneo de imágenes

La cámara escanea el material y procesa instantáneamente las imágenes a bordo.

Especificaciones y volumetría en tiempo real

Genere datos como tamaño, distribución, uniformidad, forma.

Modelos disponibles

Solo 6 Básico

Sistema especialmente diseñado que apunta al material según el tamaño máximo de partícula o la diferenciación del color del material. Este sistema es muy fácil de usar, pequeño y de diseño económico.

Nuestros sistemas de análisis están diseñados para una fácil instalación y administración remota, brindando a nuestros clientes control remoto sobre sus procesos.

- Control de separación de la trituradora

- Detección de pantallas rotas

- Clasificación basada en colores

- Detección de contaminación/dilución

El Solo 6 Basic se puede actualizar to Solo 6 Complete unlocking additional features

en cualquier momento con no se requieren cambios de hardware.

Solo 6 Complete

Measures real-time particle size, shape distribution, volume and colour differentiation of unconsolidated material. Includes features of the Basic system plus:

- Full PSD analysis of material

- 25 tamaños definidos por el usuario

- Optimice el rendimiento de SAG

- Altamente configurable

Solo 6 Features

- Completamente autónomo, opera 24-7

- Fácil de usar y fácil de instalar

- Remote management giving customers remote control over their processes

- Diseño robusto para entornos industriales (funciona de -40 °C a +80 °C)

- Performs well in harsh conditions

- Diseño de marco universal

- Fuente de luz integrada de alta eficiencia

- Utiliza WipFrag como HMI. No se requiere licencia

- Se comunica con los sistemas de control de procesos existentes (Modbus TCP, OPC UA)

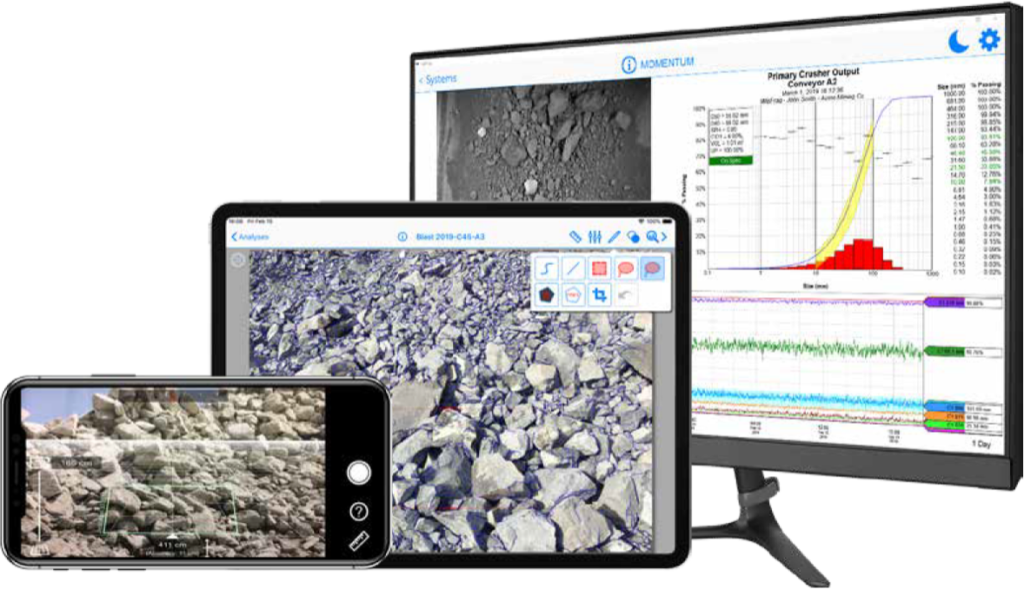

Revise los resultados en cualquier lugar a través de múltiples plataformas

Se puede acceder a los resultados de forma remota a través de una computadora de escritorio o al alcance de su mano con un dispositivo iOS o Android.

Our Solo 6 conveyor analysis system can trigger alarms to indicate oversize and even automate processes from crusher gapping to conveyor speed regulation.