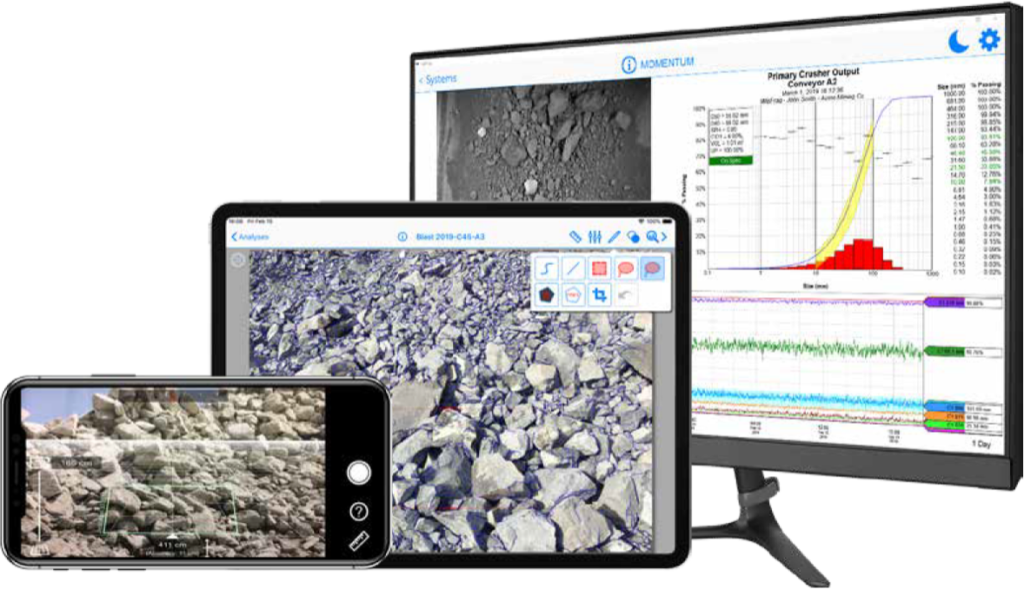

Solo™ 6 Conveyor Analysis System analyzes material on conveyor belts in real-time to automate your process, establish quality control, and improve safety, efficiency and throughput without disrupting production.

Erfassen Sie schnelle Bewegungen genau

Ermöglicht eine effektive Fernverwaltung mit verwertbaren Daten und kann Wartung, Ausfallzeiten und Energieverbrauch drastisch reduzieren.

Bedingte Ereignisse

Möglichkeit zum Senden von Signalen an einen Alarm- / SPS- / Ereignisprozess.

Sofortige Bildabtastung

Die Kamera scannt Material und verarbeitet Bilder sofort an Bord.

Echtzeitspezifikationen und Volumetrik

Generieren Sie Daten wie Größe, Verteilung, Gleichmäßigkeit, Form.

Modelle verfügbar

Solo 6 Basic

Speziell entwickeltes System, das auf Material basierend auf maximaler Partikelgröße oder Materialfarbdifferenzierung zielt. Dieses System ist sehr benutzerfreundlich, klein und wirtschaftlich konzipiert.

Unsere Analysesysteme sind auf einfache Installation und Fernverwaltung ausgelegt und ermöglichen unseren Kunden die Fernsteuerung ihrer Prozesse.

- Brecherabstandskontrolle

- Erkennen defekter Bildschirme

- Farbbasierte Sortierung

- Kontaminations- / Verdünnungsnachweis

Das Solo 6 Basic kann aktualisiert werden to Solo 6 Complete unlocking additional features

jederzeit mit Keine Hardwareänderungen erforderlich.

Solo 6 Complete

Measures real-time particle size, shape distribution, volume and colour differentiation of unconsolidated material. Includes features of the Basic system plus:

- Full PSD analysis of material

- 25 benutzerdefinierte Größen

- Optimieren Sie den SAG-Durchsatz

- Sehr konfigurierbar

Solo 6 Features

- Völlig autonom, arbeitet rund um die Uhr

- Benutzerfreundlich und einfach zu installieren

- Remote management giving customers remote control over their processes

- Robustes Design für industrielle Umgebungen (Betrieb von -40 ° C bis + 80 ° C)

- Performs well in harsh conditions

- Universelles Rahmendesign

- Integrierte hocheffiziente Lichtquelle

- Verwendet WipFrag als HMI. Keine Lizenz erforderlich

- Kommuniziert mit vorhandenen Prozessleitsystemen (Modbus TCP, OPC UA)

Überprüfen Sie die Ergebnisse überall auf mehreren Plattformen

Auf die Ergebnisse kann remote über einen Desktop-Computer oder mit einem iOS- oder Android-Gerät zugegriffen werden.

Our Solo 6 conveyor analysis system can trigger alarms to indicate oversize and even automate processes from crusher gapping to conveyor speed regulation.