Solo™ 6 Conveyor Analysis System analyzes material on conveyor belts in real-time to automate your process, establish quality control, and improve safety, efficiency and throughput without disrupting production.

Capture Swift Movements Accurately

Allows for effective remote management with actionable data and can dramatically reduce maintenance, downtime and energy consumption.

Conditional Events

Ability to send signals to an alarm/PLC/event process.

Instant Image Sampling

Camera scans material and instantly processes images onboard.

Real-Time Specifications & Volumetrics

Generate data such as size, distribution, uniformity, shape.

Models Available

Solo 6 Basic

Purpose-built system that targets material based on maximum particle size or material colour differentiation. This system is very user-friendly, small and economically designed.

Our analysis systems are designed for easy installation and remote management giving our customers remote control over their processes.

- Crusher gap control

- Detecting broken screens

- Colour-based sorting

- Contamination/dilution detection

The Solo 6 Basic can be upgraded to Solo 6 Complete unlocking additional features

at any time with no hardware changes required.

Solo 6 Complete

Measures real-time particle size, shape distribution, volume and colour differentiation of unconsolidated material. Includes features of the Basic system plus:

- Full PSD analysis of material

- 25-user defined sizes

- Optimize SAG throughput

- Highly configurable

Solo 6 Features

- Completely autonomous, operates 24-7

- User-friendly and easy to install

- Remote management giving customers remote control over their processes

- Robust design for industrial environments (operates -40°C to +80°C)

- Performs well in harsh conditions

- Universal frame design

- Integrated high efficiency light source

- Uses WipFrag as HMI. No license required

- Communicates with existing Process Control Systems (Modbus TCP, OPC UA)

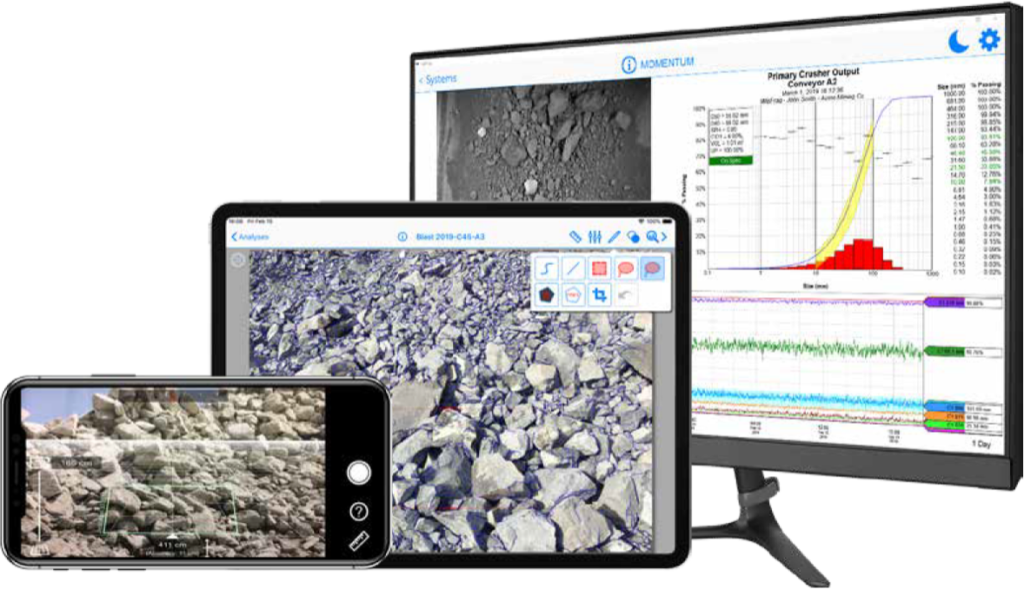

Review results anywhere across multiple platforms

Results can be accessed remotely through a desktop computer or at your fingertips with an iOS or Android device.

Our Solo 6 conveyor analysis system can trigger alarms to indicate oversize and even automate processes from crusher gapping to conveyor speed regulation.