We make solutions

to monitor, measure,

and manage materials

Because you can’t manage what you can’t measure!

Fast, reliable fragmentation measurement, wherever you need it

Industry-leading fragmentation analysis for mining, quarrying, aggregates and more — in the field, lab, or process plant.

Software for blast modeling, muckpile analysis, and operational benchmarking

Automated measurement of vehicle loads for real-time monitoring

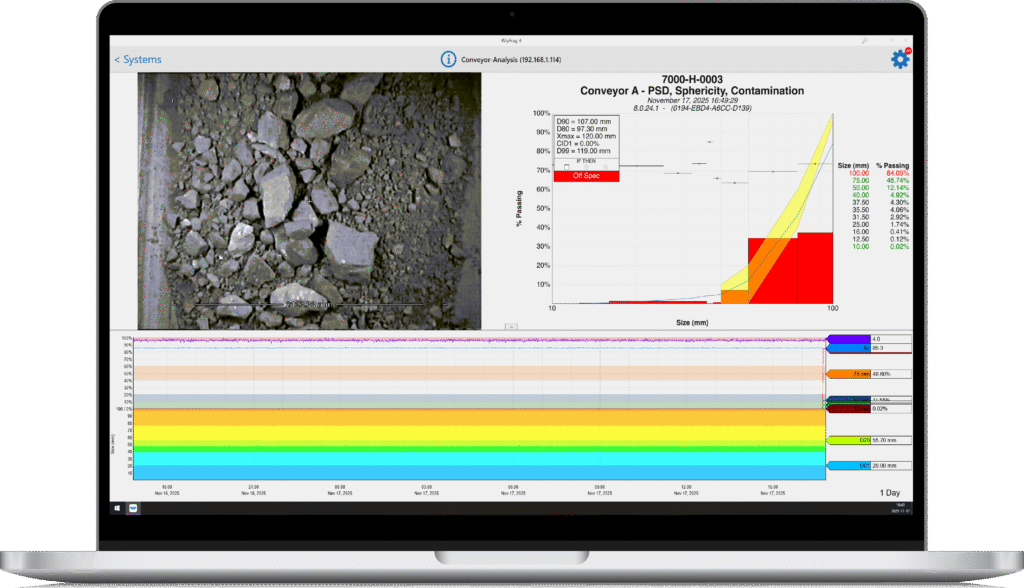

Conveyor-based fragmentation analysis for crusher and feed optimization

MONITOR

Monitor your process

in real-time

Our innovative analysis systems and fragmentation analysis software for conveyor belts, vehicles and in-the-field allow you to monitor, measure, and manage material in real-time. Collect actionable data on particle size, shape, distribution, volume, sorting by colour, and oversize detection instantly.

MEASURE

Measure fragmentation

from Pit to Plant

Complete your image analysis across multiple platforms: iOS devices, Android devices and Windows desktop. Optimize blast performance and establish quality control for particle size, shape and colour. Compatible with drones to quickly and safely generate comprehensive data with precise geographic information.

MANAGE

Manage your data

from anywhere

With remote management, you can access your data across multiple platforms, make quantitative decisions, increase productivity, reduce downtime and lower operating costs. Our technology excels at bulk material quality control, detecting broken screens, automatic crusher gapping, reducing waste, improving throughput, increasing safety and conserving energy.