Are you looking for our social media connections and information about WipWare’s products and services? Well look no further. There are several places you can find out all about us.

For WipFrag information, you can connect with our technical specialist Blessing (Giant Miner). Blessing posts interesting and informative articles about WipFrag. He is also available to assist you with any questions or schedule WipFrag training and seminars.

Giant Miner’s social media connections: Facebook, Instagram, LinkedIn, and X

Also, we have our website to provide you with information about our products and services:

Home Page – Find all the links you need to navigate our website. This includes documents to download, products, services, events and newsfeed.

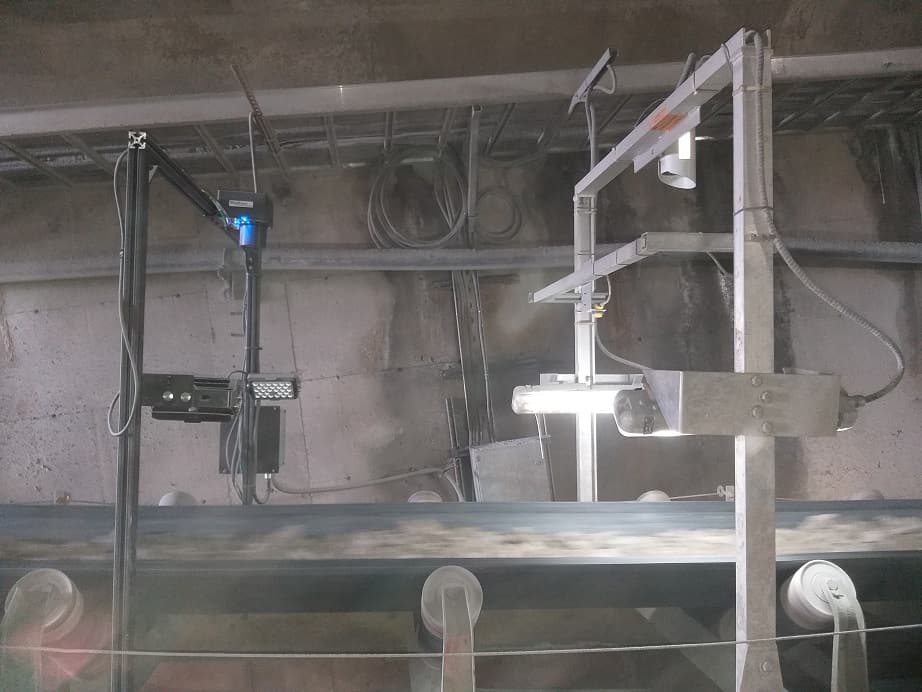

Solo™ 6 Conveyor Analysis System analyzes material on conveyor belts in real-time to automate your process. Establish quality control and improve safety, efficiency and throughput without disrupting production.

Reflex™ 6 Vehicle Analysis System focuses on acquiring high quality images that are processed onboard. Designed for use on moving HD, LHD and railcar vehicles at the primary crusher without disrupting production. Laser triggering capabilities to sense the location of the truck before capturing images. Provides real-time telemetry to your control system, data historian or automatic daily reporting.

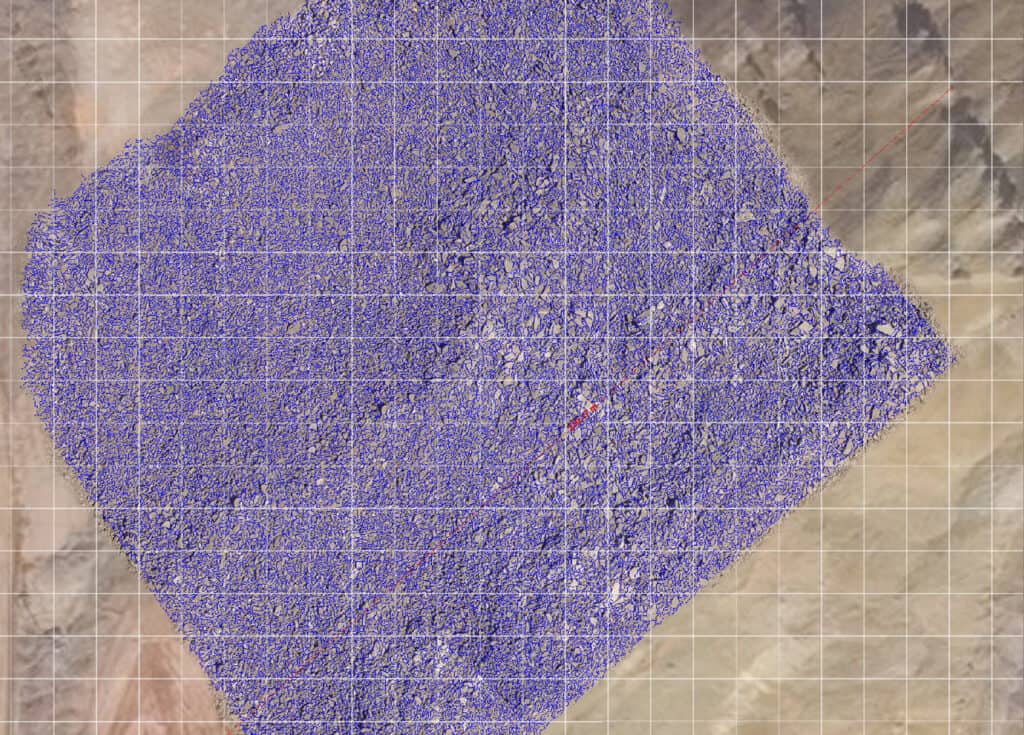

WipFrag™ 4 Image Analysis Software provides instant PSD analysis of digital images. Collect images at the muckpile after a blast, a closer up sample of a stockpile, a laboratory sample or drone/UAV images. With auto-scaling capabilities, WipFrag 4 is safe, cost effective and the most accurate fragmentation analysis tool in the world.

Also, you can make social media connections with WipWare on our social media pages.

For additional information, events taking place and product information: