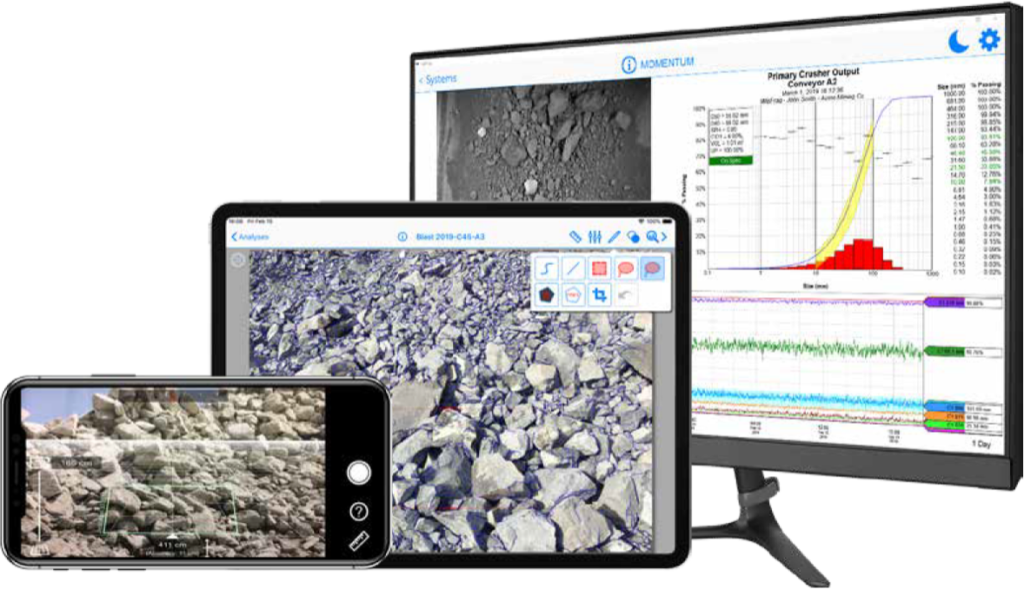

Solo™ analyzes material on conveyor belts in real-time to automate your process, establish quality control, and improve safety, efficiency and throughput without disrupting production.

Instantly measure material on conveyors

Get actionable data to enhance remote management and dramatically reduce maintenance, downtime and energy consumption. Because you can’t manage what you can’t measure!

Automated Conditional Events

Send signals automatically to your PLC or event process to stay alerted of material trends.

Instant Material Analysis

Scan material and instantly analyze onboard without disrupting the process, no network required.

Real-Time Reporting

Generate accurate data for size, distribution, uniformity, shape, and more for proactive responses.

Choose from 2 options to fit your needs:

Solo 6 De base

Purpose-built system for detecting oversize or material colour; perfect for:

- Contrôle de l'écart du concasseur

- Détecter les écrans cassés

- Oversize material diversion

- Tri basé sur la couleur

- Détection de contamination / dilution

Le Solo 6 Basic peut être amélioré to Solo 6 Complete at any time to unlock additional features with aucune modification matérielle requise.

Solo 6 Complete

Complete analysis solution including all Basic features, plus:

- Full particle size distribution (PSD) and granulometry analysis

- Material size classified in up to 25 user-defined sizes

- Particle shape distribution and volume estimation

- Colour differentiation and dilution reporting

- Fully configurable with all options available

The Solo 6 Complete is perfect for advanced material monitoring and quality control, achieving accurate measurements down to 3 mm and smaller in most applications.

Solo 6 Features

- Complètement autonome, fonctionne 24h / 24 et 7j / 7

- Convivial et facile à installer

- Remote management giving customers remote control over their processes

- Conception robuste pour les environnements industriels (fonctionne de -40 ° C à + 80 ° C)

- Performs well in harsh conditions

- Conception de cadre universelle

- Source lumineuse intégrée à haut rendement

- Uses WipFrag as HMI. No licenses or subscriptions required.

- Communique avec les systèmes de contrôle de processus existants (Modbus TCP, OPC UA)

Passez en revue les résultats n'importe où sur plusieurs plates-formes

Les résultats sont accessibles à distance via un ordinateur de bureau ou à portée de main avec un appareil iOS ou Android.

Our Solo 6 conveyor analysis system can trigger alarms to indicate oversize and even automate processes from crusher gapping to conveyor speed regulation.

Our analysis systems are designed to be user-friendly, small footprint, economical, and easy to install.