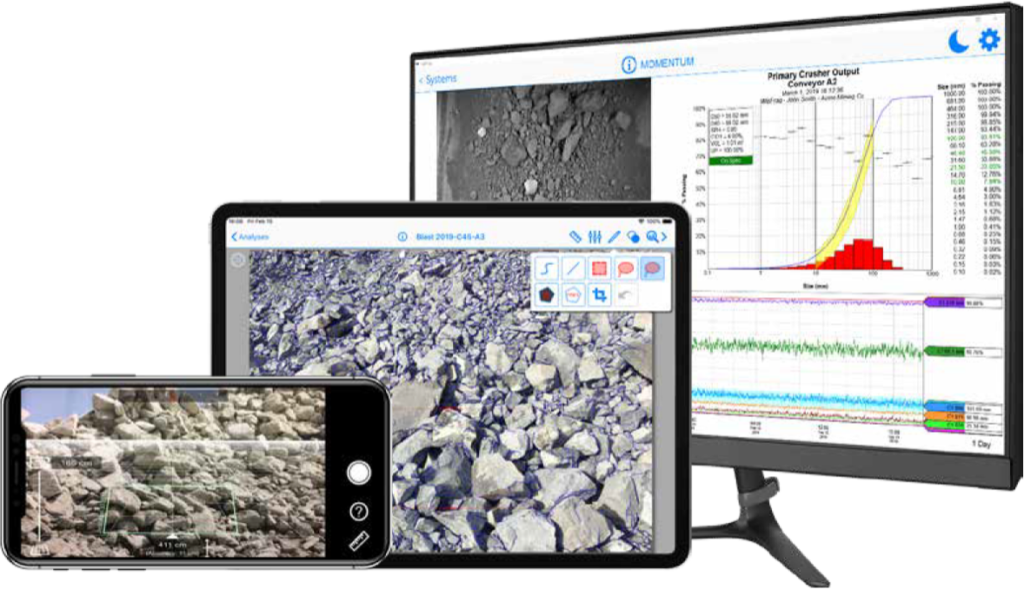

Assolo™ analyzes material on conveyor belts in real-time to automate your process, establish quality control, and improve safety, efficiency and throughput without disrupting production.

Instantly measure material on conveyors

Get actionable data to enhance remote management and dramatically reduce maintenance, downtime and energy consumption. Because you can’t manage what you can’t measure!

Automated Conditional Events

Send signals automatically to your PLC or event process to stay alerted of material trends.

Instant Material Analysis

Scan material and instantly analyze onboard without disrupting the process, no network required.

Real-Time Reporting

Generate accurate data for size, distribution, uniformity, shape, and more for proactive responses.

Choose from 2 options to fit your needs:

Assolo 6 Di base

Purpose-built system for detecting oversize or material colour; perfect for:

- Controllo dello spazio del frantoio

- Rilevamento di schermi rotti

- Oversize material diversion

- Ordinamento basato sul colore

- Rilevamento di contaminazione / diluizione

Il Solo 6 Basic può essere aggiornato to Solo 6 Complete at any time to unlock additional features with non sono necessarie modifiche hardware.

Assolo 6 Complete

Complete analysis solution including all Basic features, plus:

- Full particle size distribution (PSD) and granulometry analysis

- Material size classified in up to 25 user-defined sizes

- Particle shape distribution and volume estimation

- Colour differentiation and dilution reporting

- Fully configurable with all options available

The Solo 6 Complete is perfect for advanced material monitoring and quality control, achieving accurate measurements down to 3 mm and smaller in most applications.

Solo 6 Features

- Completamente autonomo, opera 24 ore su 24, 7 giorni su 7

- Facile da usare e facile da installare

- Remote management giving customers remote control over their processes

- Design robusto per ambienti industriali (funziona da -40 ° C a + 80 ° C)

- Performs well in harsh conditions

- Design del telaio universale

- Sorgente luminosa integrata ad alta efficienza

- Uses WipFrag as HMI. No licenses or subscriptions required.

- Comunica con i sistemi di controllo di processo esistenti (Modbus TCP, OPC UA)

Esamina i risultati ovunque su più piattaforme

È possibile accedere ai risultati in remoto tramite un computer desktop oa portata di mano con un dispositivo iOS o Android.

Our Solo 6 conveyor analysis system can trigger alarms to indicate oversize and even automate processes from crusher gapping to conveyor speed regulation.

Our analysis systems are designed to be user-friendly, small footprint, economical, and easy to install.