Introduction

In the field of mineral processing and comminution (crushing and grinding), accurate size analysis is essential for optimizing the performance of crushing circuits and downstream processing units. Effective rock breakage using explosive energy requires a well-optimized blast design to ensure the energy is directed into the rock mass for maximum fragmentation and minimal waste. A properly executed design enhances breakage efficiency, improves downstream processing, and produces consistent material sizes measurable through Particle Size Distribution (PSD), which represents the proportion of different particle sizes within a fragmented material sample. One of the most critical parameters used in particle size distribution (PSD) analysis is P80, which stands for the particle size at which 80% of the sample material passes. This article discusses the definition, importance, and application of P80 in the crushing process and overall mineral processing operations.

What is P80?

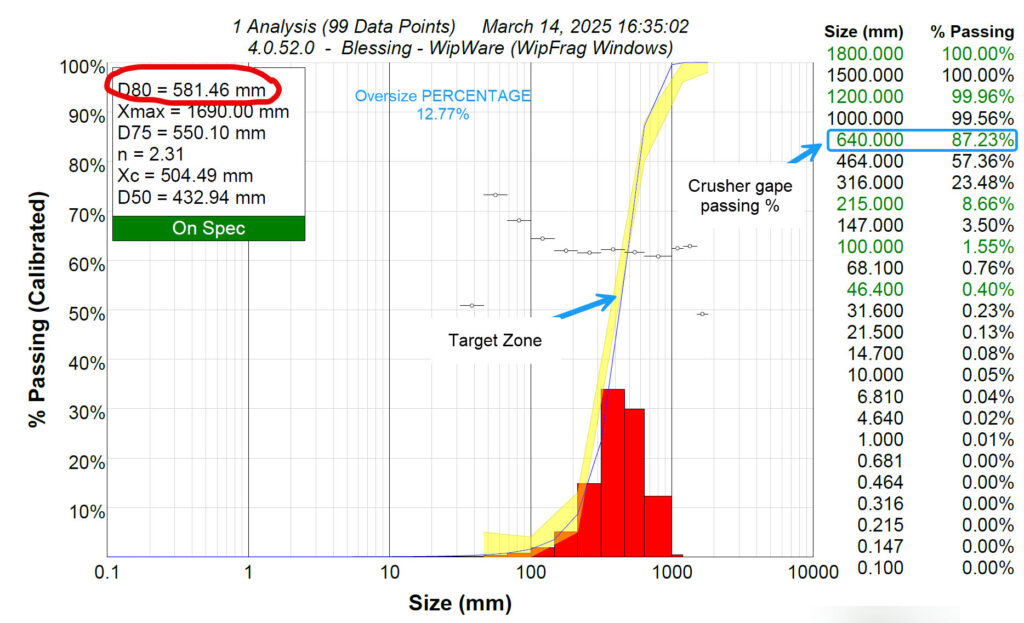

P80 refers to the particle size (usually expressed in micrometers or millimeters) at which 80% of the sample’s mass passes through a given screen size. It is derived from the particle size distribution curve and provides a representative measure of the overall coarseness or fineness of a crushed or ground product.

For example:

- If the P80 of a crushed ore is 120 mm, it means that 80% of the mass of that sample will pass through a 100 mm screen.

How is P80 Determined?

P80 is typically determined through:

- Sieve Analysis: The material is sieved using a stack of screens of decreasing mesh size. The cumulative mass retained is plotted to generate the PSD curve.

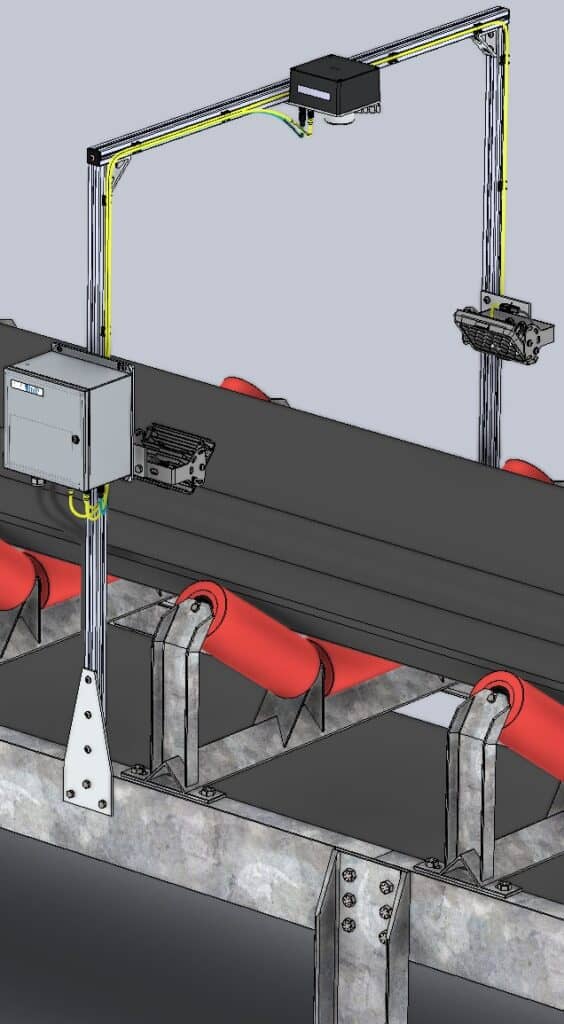

- Automated system: In automated systems like WipFrag 4, Reflex 6, а также Solo 6, image-based particle size analysis can generate PSD curves without physical sieving, using photoanalysis techniques.

Importance of P80 in Crushing and Mineral Processing

1. Crusher Design and Operation Control

The efficiency of crushers and grinding mills is largely influenced by the target P80:

- Primary crushers may target a P80 of around 100–150 mm.

- Secondary crushers aim for a P80 of 20–40 mm.

- Grinding mills (ball or SAG mills) often target a P80 of 75–150 µm for mineral liberation.

Setting and monitoring a P80 helps ensure the crushing process delivers the required product size for efficient downstream separation.

2. Grinding Circuit Efficiency

The Bond work index (BWI) is a well-known method used when selecting comminution equipment, to evaluate the grinding efficiency and to calculate the required grinding power (Nikolić et al., 2021). Determining the BWI is part of the design phase of a mining plant and can significantly affect the design costs associated with comminution. Mining comminution processes are the most energy intensive, and also the area with the greatest potential for energy savings. Accurate determination of the BWI is essential for the proper design and estimation of the costs associated with the comminution process.

P80 is critical in the Bond Work Index (BWI) equation:

W=10×Wi×((P80^-0.5)−(F80^-0.5))

Where:

- W is the energy required (kWh/t),

- Wi is the Bond Work Index,

- F80 is the 80% passing size of the feed,

- P80 is the 80% passing size of the product.

This relationship shows how energy input depends on the size reduction from F80 to P80. Thus, optimizing P80 can reduce energy consumption and cost.

3. Liberation and Recovery

In mineral processing, liberation of valuable minerals is essential before separation (e.g., flotation, leaching, magnetic separation).

- If P80 is too coarse, incomplete liberation may occur, reducing recovery.

- If P80 is too fine, overgrinding may lead to slimes that reduce separation efficiency and increase reagent consumption.

An optimal P80 ensures maximum liberation with minimal energy and operating cost.

4. Crusher-Compatibility and Throughput

When processing material through a plant, particularly in multi-stage crushing, each unit must receive appropriately sized feed:

- Oversized material can cause crusher choking or blockages.

- Undersized material may result in under-utilization of capacity.

By targeting a consistent P80:

- You ensure crusher feed compatibility.

- You maintain steady throughput and minimize downtime.

5. Process Control and Optimization

In modern mineral processing plants, real-time monitoring of P80 allows dynamic control:

- Adjusting crusher settings (CSS),

- Managing screen decks or vibrating screen performance,

- Automating grinding media addition in mills.

Image analysis tools likeSolo 6enable on-belt PSD analysis, providing operators with live P80 data for feedback control either before crushing or after crushing.

Factors Influencing P80

Several factors impact the actual P80 of a crushed or ground product:

- Rock hardness and competency

- Crusher/mill type and operating parameters

- Blasting quality and fragmentation

- Screening efficiency

- Ore variability and moisture content

Continuous monitoring and adjustment are crucial for maintaining a consistent P80 under changing conditions.

Typical P80 Targets by Process Stage

Primary Crushing: 100 mm – 250 mm

Secondary Crushing: 20 mm – 80 mm

Tertiary Crushing: 5 mm – 20 mm

SAG Mill Discharge: 1 mm – 3 mm

Ball Mill Product: 75 µm – 150 µm

Flotation Feed: 106 µm – 150 µm

Leach Feed: 50 µm – 100 µm

Conclusion

P80 is one of the most significant performance indicators in crushing and material processing. It serves as a benchmark for:

- Crusher performance evaluation

- Grinding circuit design

- Energy efficiency analysis

- Liberation optimization

- Quality control and process automation

A well-controlled P80 not only improves the economics of mineral processing but also ensures better recovery and operational stability. With the rise of automation and image-based analysis systems, monitoring and optimizing P80 has become more precise and actionable, empowering engineers and operators to make data-driven decisions.

Reference