Real-time material measurement on the conveyor, enabling crusher & process-feed optimization

Instantly measure material on conveyors

How Solo Fits in the Value Chain

The conveyor is your earliest and most consistent control point — and Solo turns it into a powerful source of real-time process intelligence. Solo gives you the insight to:

- Catch problems early — detecting oversize, excessive fines, or unexpected material before it affects crushers or mills.

- Protect equipment by identifying sudden feed changes, out-of-spec loads, or conditions that could cause overloads or stalls.

- Stabilize throughput by ensuring consistent, predictable feed into downstream processes.

- Improve energy efficiency by maintaining uniform fragmentation and reducing grinding variability.

- Enhance ore control and blending with continuous insights on colour, ore type, and contamination.

- Validate blast performance by comparing conveyor PSD trends over time.

- Enable intelligent automation through alarms, diversions, or process adjustments triggered by live data.

What Solo Does

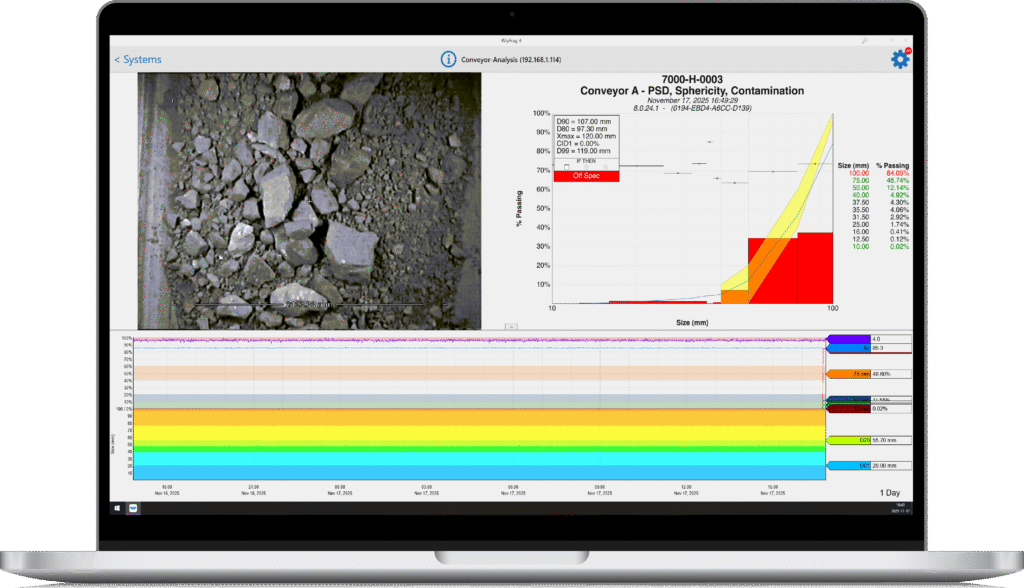

Solo is an autonomous vision system that continuously measures material moving on your conveyor, delivering fast, accurate data for process control.

Solo provides:

- Full particle size distribution (PSD) updated every few seconds

- Shape and uniformity metrics for fragmentation quality

- Oversize identification with automated alarms or rejection triggers

- Trend analysis to monitor feed stability and crusher/mill performance

- Colour-based detection of ore type shifts, dilution, or contamination

- Real-time data integration with control systems (Modbus TCP / OPC UA) for closed-loop control

- 24/7 autonomous operation with low maintenance requirements

Solo Options: Choose the Capability You Need

Solo is available in two configurations, both built on the same hardware platform. Start with the essentials — or unlock full analysis capabilities from day one. Upgrading between versions requires no hardware changes.

Соло Базовый

A streamlined solution for real-time detection and simple process control; ideal for:

- Oversize detection

- Контроль зазора дробилки

- Identifying broken screens

- Colour-based sorting or contamination detection

Perfect when you need fast, reliable alerts without full granulometry.

Соло Complete

Everything in Basic, plus advanced analytics for full material insight:

- Full particle size distribution (PSD)

- Up to 25 user-defined size classes

- Shape distribution and volume estimation

- Advanced colour differentiation and dilution reporting

Designed for operations that need comprehensive, high-accuracy monitoring.

Our analysis systems are designed to be user-friendly, small footprint, economical, and easy to install.

Proven Performance

See how our customers are using Solo

Read about using Solo to measure blast fragmentation and optimize mill throughput

Typical Applications

- Crusher-gap control and oversize diversion

- Feed-stock uniformity monitoring to stabilise SAG/AG mills

- Contamination or dilution detection (colour/texture)

- Real-time process control (belt speed/throughput adjustments)

- Quality control of feed material and process optimisation

Get Started with Solo

Solo is installed, commissioned and calibrated by our specialist team and can be tailored for your conveyor width, material type and process environment.

Contact us today for a detailed quotation or to schedule a demo.