How Low Can you Go?

One of the more common questions we receive is “how low can you go”? If you refer back to this blog post, you will be able to see that we can analyze down to microns if the proper image is taken. When it comes to conveyor belt applications, there are additional factors affecting the size ranges WipWare can analyze down to.

We have dealt with a massive range of conveyor belt sizes over the years. WE have worked with mini 10-inch conveyor belts at some of the highly quality-control based clients. As well, the massive copper and iron ore run-of-mine conveyors around the globe. Thankfully, the frames we provide are fully adjustable. We customize these frames prior to shipping to your operation to ensure a successful application.

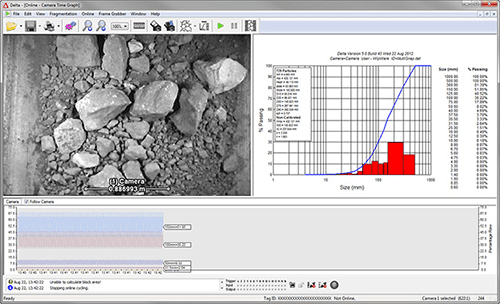

Conveyor Belt Analysis

Let’s get a few of the basics out of the way when it comes to conveyor belt analysis:

- The distance between belt and camera is typically fixed within a few inches/millimeters.

- The lighting conditions tend to be more ideal.

- The stream of material is typically within a small range (covering, say, three-quarters of the belt as an example).

- If you only have one camera located in your operation, you need to contact us because chances are there’s potential for additional cameras that will further optimize your process.

Given these controlled conditions, we can really nail down the size ranges our systems analyze for your specific application. Let’s use a couple examples that reflect the field of view considerations:

- Copper operation ABC uses a 10ft. (~3000mm) conveyor belt for a run of mine application for post-primary crusher optimization.

- Gold operation XYZ uses a 4ft. (~1200mm) conveyor belt for a SAG feed application.

Height of the system on the conveyor belt

Because of the width of the conveyor belt at the copper operation, our particle sizing systems need to be placed higher above the conveyor in order to reach the full range of material spread, and this plays an important role in determining the range of finer material we can analyze. We will be able to key in on coarser size fractions running on the belt, and let’s face it – if you have a 10ft. belt in place, chances are you aren’t running 100% fines on it. Using the WipWare Camera Selection Matrix, we can identify that with a 1.2mp camera, we will be capable of analyzing down to 0.2813 inches (7.14mm), and a maximum range of 24 inches (609.60mm).

Because the material at Gold operation XYZ has already been through a crushing and grinding circuit the material size is quite a bit smaller our systems will be able to analyze down to a smaller size due to the width of belt / height of the camera. In this case, with a 1.2mp camera we would be able to analyze down to 0.1125 inches (2.86mm) and up to 9.6 inches (243.84mm).

What type of wiggle room do we have on the min and max size ranges?

Well there’s a couple of options to consider if you want to expand the range:

Upgrade to a 5.0mp camera; this is a common upgrade that clients opt for in order to expand their minimum size limit.

Reduce the field of view; as noted earlier, wider conveyor belt applications require higher distances between the head and material. If fine material is of utmost importance to your application, WipWare can reduce the field of view range to amplify your fine material analysis. However, if we go too far when reducing the field of view, we will be analyzing fines at the expense of picking up coarser size fractions.

Next time you pass a conveyor belt and wonder how effective an online system will be at analyzing the fine material, consider contacting us and finding out more about how our conveyor belt technologies have helped clients around the world. Have a specialty application? We always like a challenge! Send us the details and we will be happy to help.