Blast Design

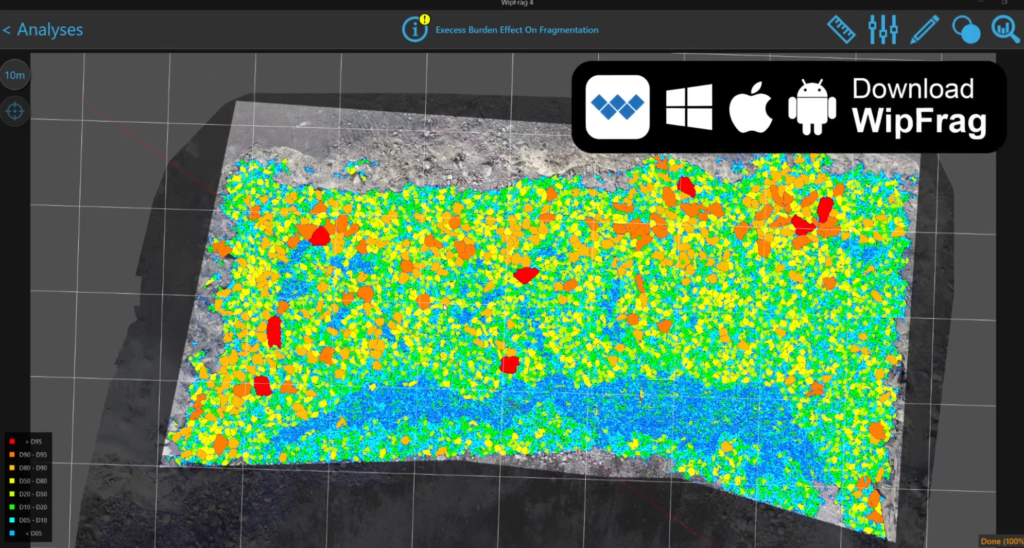

What are the causes of Excessive burden in blast design and how to identify blast fragmentation that result from excessive burden or other ill blast design using WipFrag 4.

Starting with this quote from Singh et al. (1998), the mentioned that “Drilling errors are frequent but undesirable occurrences in mining operations and are composed of collaring, alignment, trajectory and length errors. Improved drilling accuracy has tremendous monetary benefits in terms of optimum fragmentation, reduced dilution, higher ore recoveries and less need for redrilling.”

Poor Drilling Operations Result

Going forward, the large effect of poor drilling operations on excessive burden creation necessitates a comprehensive assessment of blasting practices. Each mine requires a robust methodology for bore hole and blasting result assessment as this is essential for improving the predictability and overall efficiency of mining operations.

Considering the heterogeneous state of rock mass and the varying conditions of human operators and drilling machinery, below are some of the factors that contribute to excessive burden distance in blast design:

Factors that Contribute to Excessive Burden Distance in Blast Design

1. Rock Mass Variability: Differences in rock strength, density, and structure can lead to uneven excessive burden creation.

2. Blast Hole Deviation and accuracy: The deviations in drill holes from their intended (design) paths due to rock anisotropic characteristics can create inconsistencies in burden and spacing (Bradley, 1975).

3. Explosive Distribution: Considering the explosive energy per meter along borehole wall, Uneven distribution or incorrect loading of explosives can lead to improper energy release, affecting burden distance at detonation.

4. Rock Mass Discontinuities: The Presence of joints, faults, and fractures can also influence blast outcomes, causing uneven burden distribution.

5. Blasting Practices: Variations in blasting techniques and practices, including timing and sequence, can impact burden and fragmentation.

6. Equipment Performance: Drilling Equipment Wear and tear, maintenance issues, and technological limitations are one of the well known factor that affects drilling precision and blast outcomes.

7. Human Factors: Operator skill, experience, fatigue, and adherence to procedures play a significant role in achieving accurate drilling and blasting.

8. Environmental Conditions: Weather, ground conditions, and water presence can affect drilling performance and blast effectiveness.

One of the significant evidence of blasting with excessive burden distance is having oversize accumulation in blast result along throw path.

The video attached shows how to assess this using WipFrag 4 software:

In the Part 4 of this article, I will discuss some of the ways to avoid excessive burden effect on blasting fragmentation.

Follow and share: https://www.facebook.com/GiantMiner

Missed Part 1 and 2? Here you go:

Part 1: Effect of Excessive Burden Distance on Blasting Result – Part 1

Part 2: https://wipware.com/effect-of-excessive-burden-distance-on-blasting-result-part-2/