By: Paul Chivers

Blast prediction is tricky business. The variables are many and there are always unknowns. Achieving ideal fragmentation is critical to controlling costs for many operations.

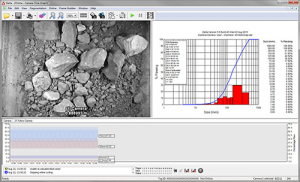

BlastCast, a blast fragmentation prediction module recently introduced as a free enhancement to WipWare’s regarded WipFrag software, is another tool to help clients resolve fragmentation issues. Blast Cast works in conjunction with WipFrag data to help you forecast and move your fragmentation in the desired direction.

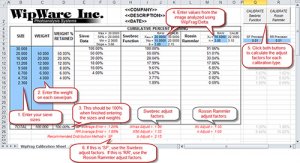

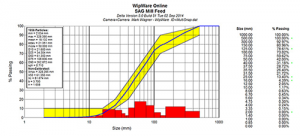

You start by entering the parameters of a particular blast. BlastCast will predict the resulting fragmentation in a particle size distribution graph. The next step is to measure the resulting fragmentation using WipFrag software to determine actual fragmentation. Drag the results into the BlastCast window to superimpose actual fragmentation over predicted fragmentation. Now you can adjust the Rock Factor slider to shift the prediction curve towards the actual fragmentation curve.

Once you have calibrated the model, you can experiment with other blast parameter sliders to see how changing the spacing might affect fragmentation or other scenarios. The more you use BlastCast, the more accurate it becomes.

An explanation of the various sliders in the BlastCast module follows:

By default, BlastCast accepts whatever size classes are set in the WipFrag Output Options.

Metric/Imperial Radio Buttons: Choose preferred unit of measurement.

KCO Model – Kuz-Ram Model Radio Buttons: Choose between KCO Model (Kuznetsov-Cunningham-Ouchterlony) containing three parameters – xmax, x50, and xB – based on the Swebrec Function, or, the Kuz-Ram Model, (Kuznetsov-Ramler) containing two parameters – xc and N – based on the Rossin-Ramler Function.

Blast Values Checkbox: Leave on most of the time. Locks top section of interface. When unchecked locks bottom section of interface.

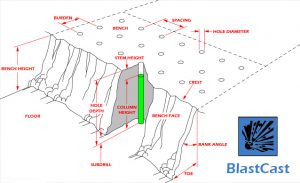

Burden: Distance between borehole and the face.

Spacing: Distance between rows of bore holes.

Diameter: Diameter of bore hole.

Drill Accuracy: Often a function of drilling equipment; accounts for twists, turns, and deflections. Usually a relatively low number and usually constant.

Bench Height: Bench or face height.

Density: Obtain specification (gm/cc) from explosive manufacturer’s Blasters’ Tables/Guides.

Rock Factor: Hardest factor to determine; includes 6 or 7 parameters tied together including modules of elasticity and in-situ joint planes.

Relative Weight Strength: Indicates how powerful an explosive is related to standard ANFO, which has a Relative Weight Strength of 1.00. Obtain specification from explosive manufacturer.