We’ve put together some photoanalysis systems FAQs based on questions from our customers.

WipWare Image Analysis Systems produce real-time 24/7 results that allow personnel to identify, evaluate, and optimize troublesome areas of their process while maintaining production.

Our systems are installed in many different applications around the world. These applications vary from analyzing wood chips to detecting oversize material or contamination in diamond mines. The applications are endless.

From Mine to Mill

The term Mine to Mill highlights the importance of fragmentation data on both the blasting and processing end of operations. This term applies well to WipWare line of products from the muckpile after a blast to analyzing material on the conveyor.

Mine-to-mill technology takes the entire system into account, from the blasting process to the comminution circuit. This optimization provides a complete fragmentation and size reduction solution to maximize benefit.

Software de análisis de imágenes WipFrag

WipWare’s WipFrag 4 Image Analysis Software effectively analyzes data from a recent blast and produces results of the blast material on-site in minutes.

Sistema de análisis de vehículos Reflex

From there, as the trucks haul the material to the primary crusher, you can detect oversize material or contamination and divert the material accordingly.

Once at the primary crusher, our Reflex systems can detect oversize material, contamination or give full particle size distribution analysis as the material is dumped.

Sistema de análisis de transportador individual

After the material has gone through this process our systems can continue to analyze the material on the conveyor belt.

At this stage, you can determine what is the most important information you want to retrieve: detect oversize, divert material, identify contaminated material or receive full Particle Size Distribution data 24/7 in real-time.

Now, here’s the cool part: our WipFrag software is also the HMI (Human to Machine Interface) for our systems. Not only can you use our software separately to analyze your blast material, but the same software is also used to analyze your material all along its journey from Mine to Mill.

Many potential customers ask this very question about the benefits of WipWare products. Well, here’s the answer.

WipWare offers industry-leading photoanalysis technology for accurate, real-time fragmentation assessment, optimizing blasting, crushing, and grinding operations. With features like deep learning, auto-scaling, GIS compatibility, and orthomosaic analysis, WipWare ensures precise measurement and continuous improvement. The software’s specification envelope, histogram reporting, and boulder counting enhance decision-making, reducing downtime and costs. Additionally, WipWare provides flexible pricing, cross-shipping warranties, and expert support, making it the top choice for efficient mining and aggregate operations.

Furthermore, our online Systems provide data to the customer 24/7 to identify troublesome areas of your process from Mine2mill.

In conclusion, our Solo Basic or Complete, Reflejo Basic or Complete and WipFrag software can drastically lower energy, and maintenance costs, as-well as cut equipment downtime and aid in quality control.

WipWare uses precise belt-depth detection lasers to detect both

A) Empty belts, as with previous Solo models

B) The depth of material on the conveyor belt

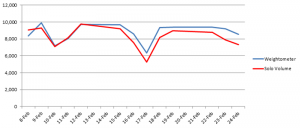

When you tie the material depth information with the conveyor belt speed and your belt weightometer reading, you are able to extract the specific gravity of the material passing. Having the specific gravity information will allow you to determine whether the material passing is waste or ore-bearing material.

In preliminary tests at a limestone operation, WipWare was able to reach 94% correlation between the volumetric calculations and the belt weightometer readings.

An operation could use this information to divert waste material from entering the crushing process, saving significant amounts of money in maintenance and energy costs.

Volumetrics users have the added benefit of receiving accurate particle sizing results as well as another new feature allowing you to detect contamination.

With size, shape, volume and contamination detection data being streamed seamlessly in real-time, WipWare’s automated technologies are providing three times as much accurate data metrics than competitors.

En WipWare, a menudo nos denominamos proveedores de tecnología de minería y agregados, ya que estas dos industrias constituyen la mayor parte de nuestro negocio. La belleza de las tecnologías de fotoanálisis es que, con una imagen adecuada, nuestros productos pueden analizar cualquier cosa, desde material de micras hasta planetas. Todos sabemos que el dimensionamiento automatizado de partículas es una parte crucial de la industria minera y de agregados, pero como verá, el tamaño del material no solo es importante para las rocas. Estas son algunas de las aplicaciones geniales con las que hemos tenido el placer de trabajar:

Rover Curiosity de Marte: There may not be any mining on Mars (that we know of), but the Curiosity rover is taking pictures that are being analyzed for oversized obstacle detection. What a great way to identify and steer clear of obstacles and keep Curiosity roaming.

Huevos revueltos. That’s right, I said scrambled eggs. A food supplier from the US contacted us looking to optimize the fluffiness and fragmentation of the scrambled eggs they use. I’ll never look at scrambled eggs the same way ever again.

Kimberlita procesada: Getting out of our chef’s apron and putting our hard hats back on, we have been working very closely with multiple diamond companies around the world to accurately analyze the process kimberlite material on their conveyor belts. What’s so incredible about this application? Well, it’s pretty normal, except for the fact that the material ranges from as low as 1.2mm (0.0472440″ for our Imperial friends). Once again, if a suitable image can be captured, WipWare can analyze it.

…And of course, we work with hundreds of applications that deal with broken screen detections, contamination, quality control procedures, pre- and post- crusher optimization and SAG mill throughput applications.

Both Delta (Solo 6 and Reflex 6) and WipFrag produce a percentage passing curve visible after each virtual sieve analysis. It also saves the data to a CSV (comma-separated values) file. Each sieve analysis produces a new line in the CSV file that represents the results from the sieve.

Este archivo CSV contiene:

– Timestamp (Year/Month/Day/Hour/Minute/Second)

– D-values (XX% passed the specified size – Ex. 90% of the material passes 13.87 inches[352.30mm])

– User specified size classes (% passing or retained at the specified size)

– Block (amount of particle detected)

– Min, Max, Mean, St. Dev, Mode

– Sphericity (The shape of the material – 0=Linear Objects 1=Perfectly Round)

– Coverage (How much of the image is used)

– Calibration Values (b, Xmax, X50, Xc and n)

– EDP values (Edge Detection Values)

– Calibration factors

– System info (CPU temp, Board temp, Voltage checks)

– System uptime

– Camera setting at the time of the image.

– Modbus and OPC poll rate

– Vehicle Identification Information (Reflex Only)

Delta (Solo 6 and Reflex 6) can e-mail these CSV files automatically as well as an average of the entire day on one passing curve. It also has a trending graph in the lower section of the software interface which trends the data for the current day.

Además, Delta tiene la capacidad de generar la información de análisis utilizando una conexión Modbus u OPC para pasar información a su historiador, PLC o HMI.

El único mantenimiento regular requerido para nuestros sistemas es asegurar que la lente y las luces estén limpias con la menor cantidad de polvo/suciedad posible.

La frecuencia con la que será necesario limpiar el sistema dependerá del entorno en el que opere:

AMBIENTE/ FRECUENCIA

Muy polvoriento 1-3 semanas

Polvo moderado 2-6 semanas

Poco o nada de polvo 4-8 semanas

Método 1: Manguera de agua

The first method is the most common. Using a water hose, simply spray down the system ensuring the lens is clean and free of any noticeable dust or dirt. If possible, use a squeegee to remove any droplets that may remain on the lens. Doing this helps prevent dust from collecting in the droplets that remain which could leave deposits on the lens that interfere with image capture. Since our systems are completely waterproof this method is usually the easiest and most effective way to clean the lens. It can also be done without having to shut down the conveyor belt.

Método 2: paño húmedo limpio/toalla de papel

Otra opción es usar un paño limpio y húmedo o una toalla de papel con agua o Windex. Lo ideal sería usar un paño de microfibra limpio, pero puede ser difícil encontrarlo en las minas. Trate de no presionar demasiado cuando limpie la lente, el polvo acumulado podría dejar rayones en la lente si se aplica demasiada presión. Nota: En temperaturas bajo cero, absténgase de usar agua o Windex, ya que se congelará en la lente y causará una calidad de imagen inadecuada. Recomendamos usar un lavaparabrisas estándar que esté clasificado para la temperatura bajo cero correcta.

Método 3: aire comprimido

It’s also acceptable to use compressed air from a can or hose to dust off our systems. This method works well but will kick up a lot more dust than the liquid methods. We recommend using a dust mask when using compressed air to clean off out systems.

La respuesta simple es sí.

The computer can store up to 1000MB worth of images without any issues. Once beyond this point the hard drive could start having problems accessing the image folder causing the computer to run slower than normal, so the oldest images are overwritten automatically.

Nota: Todos los datos del tamaño de las partículas se guardan en un archivo CSV que tiene un tamaño mucho más pequeño y le permite almacenar datos durante una línea de tiempo más larga.

La mayoría de nuestros sistemas utilizan una cámara de 1,2 MP y las imágenes tienen un promedio de 180 KB cada una, por lo que 1000 MB de almacenamiento pueden acomodar aproximadamente 5600 imágenes.

Running 24 hours per day the system can roughly save the following number of images:

Si está tomando 1 imagen cada 20 segundos, tendría 4320 imágenes por día. ~31,2 horas

Si está tomando 2 imágenes cada 20 segundos, tendría 8640 imágenes por día. ~15,5 horas

Si está tomando 3 imágenes cada 20 segundos, tendría 12,960 imágenes por día. ~10,3 horas

To calibrate, or not to calibrate; that is the question. And it’s an important question to ask prior to installing your online bulk material analysis system, regardless of the industry you’re in. Let’s help you figure out why calibration may or may not be your best bet, and whether you will see value in calibrating your system.

Una de las deficiencias de la tecnología de análisis de fragmentación de rocas basada en imágenes es la incapacidad de analizar el material subyacente que corre sobre una cinta transportadora. Por lo tanto, en circunstancias normales, sin calibración, el material fino suele estar subrepresentado cuando se utiliza el análisis de imágenes. Lo mismo puede decirse del análisis de fragmentación de voladuras, pero hablaré de esto un poco más adelante en el artículo.

Si las tecnologías de análisis fotográfico representan material en la capa superior y subrepresentan el material subyacente, una operación puede compensar esta deficiencia mediante la calibración. (Para obtener la guía práctica sobre calibración, consulte este enlace).

The way I see it, without sounding too much like a broken record, calibrated photo analysis technologies take the best of both worlds: Quantity and quality.

Take the following scenario as an example: Company ABC wants to adjust the SAG feed based on particle size analysis. By doing so, they need to know when to draw fine material from the stockpile and when to draw coarser material. Calibration allows for the proper “mix” of bulk material in order to optimize the process.

The Swebrec and Rosin-Rammler functions are great for adjusting the distribution curve to accurately compensate for fine material… But what if you are looking strictly at the coarse sizes, say, for oversize detection?

If this is the case, you may want to reconsider the calibration process.

Allow me to explain:

A calibrated system is making certain assumptions about material underneath the top layer and may even bias your coarse material fractions when trying to adjust the distribution curve. So, if you are planning on having a conveyor belt shut down if it detects material over x size, you may want to reconsider taking the chance of biasing your results. Instead, an uncalibrated system is going to get you very useful data that will allow you to stop/start/act on out-of-spec readings and optimize your process.

What are other reasons why clients don’t calibrate?

Cuando el material es demasiado grande, es mucho más difícil muestrear manualmente el material y esto podría tener un costo prohibitivo. Este problema surge con mayor frecuencia en el extremo de la aplicación de voladuras, donde la optimización de las voladuras depende en gran medida de la detección de cambios relativos en el tamaño del material.

Para el análisis posterior a la trituración, algunos clientes detectan el desgaste del revestimiento por aumentos relativos en el tamaño del material, lo que hace innecesaria la calibración.

En resumen, la calibración ciertamente tiene sus usos dentro de las industrias de minería y agregados, y más específicamente, cuando los tamaños de materiales más finos son una parte necesaria del dilema; sin embargo, los sistemas no calibrados siguen siendo muy útiles para optimizar su proceso y para realizar un seguimiento de los cambios relativos.

WipWare Inc. provides a one-year limited warranty on all products, including components and software. To offer customers peace of mind, WipWare also offers an annual service contract, which includes exclusive technician service rates, monthly check-ins, extended system warranties, and more.

With the purchase of any WipWare photoanalysis product, the warranty covers cross-shipping for any defective product under the WipWare Limited Warranty, ensuring minimal downtime for customers.

Para obtener detalles completos de la garantía limitada de WipWare, consulte aquí.

WipWare goes above and beyond to ensure that not only customers, but any individual or company who may show interest in a WipWare product has the utmost training and confidence when it comes to utilizing our extensive line of photoanalysis systems. WipWare offers free training to individuals, companies, colleges, and universities interested in learning about our products. We recently conducted on-campus workshops for mining students at Queen’s University (Kingston), Laurentian University (Sudbury), and ÉTS University (Montreal). In addition to in-person sessions, we provide virtual training and have a library of training videos available for easy access.

For more information about WipWare training please contact support@wipware.com

For more information about our systems, please visit our YouTube channel.