March Newsletter

Introduction

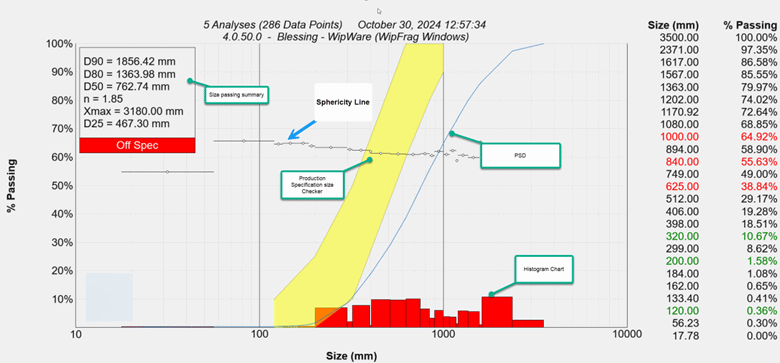

WipFrag software provides detailed fragmentation analysis through histograms and Particle Size Distribution (PSD) charts. These tools help users assess particle size consistency and shape uniformity, which are critical for optimizing blasting and crushing operations. Two among the key elements in WipFrag analysis are the histogram e il sphericity lines on the PSD chart.

Interpreting the WipFrag Histogram

The histogram in WipFrag displays the frequency of particle sizes within specific bins, helping to visualize fragmentation trends. Here’s how to analyze it:

- X-Axis (Particle Size Ranges): Represents particle size classes based on the sieve analysis standard.

- Y-Axis (Frequency or Percentage Passing): Shows the proportion of material in each size class.

- Histogram Shape:

- A normal distribution suggests well-balanced fragmentation.

- A right-skewed distribution indicates excessive fines.

- A left-skewed distribution suggests large boulders dominate.

By analyzing the histogram, users can determine whether the blast produced the desired fragmentation or if adjustments are needed in blast parameters.

Understanding Sphericity Lines on the PSD Chart

Sphericity represents the ratio of particle length to width, indicating shape uniformity. WipFrag incorporates sphericity lines on the PSD chart to provide insight into particle geometry:

- 100% Sphericity: Indicates perfect uniformity (equal length and width).

- 70-90% Sphericity: Represents well-shaped, near-uniform particles, ideal for crushing and handling.

- Below 70% Sphericity: Suggests elongated or irregularly shaped particles, which may impact flowability and crusher efficiency.

Why Sphericity Matters

- Higher sphericity (>70%) improves material flow and crusher compatibility.

- Lower sphericity (<70%) may cause blockages in crushers and conveyors.

- Well-distributed sphericity values indicate a good mix of particle shapes.

Interpreting WipFrag histogram and sphericity lines helps assess fragmentation quality and shape uniformity. By understanding these parameters, mine operators can fine-tune their blasting strategies for optimal size distribution and material handling efficiency.

Download WipFrag here: https://wipware.com/products/wipfrag-image-analysis-software/

How to Use WipFrag for Blasting Quality Control (QC)

WipFrag, a leading photoanalysis software, enables real-time fragmentation assessment, helping engineers and operators maintain blasting quality control (QC) and improve efficiency.

Step-by-Step Guide to Using WipFrag for Blasting QC

- Image Capture and Data Collection

- Capture high-quality images of the blast muck pile using a UAV (drone), camera, or mobile device.

- Ensure proper lighting and image clarity for accurate particle detection.

- Use WipFrag’s Auto Scale feature or place a scale reference in the image for precise measurements.

- Image Processing and Fragmentation Analysis

- Upload images into WipFrag software.

- Use the Edit Assist tool to refine particle outlines and improve accuracy.

- Generate a Particle Size Distribution (PSD) curve to analyze the fragmentation results.

- Assessing Fragmentation with Histograms and PSD Charts

- Histogram Analysis: Identify particle size frequency and distribution trends.

- Specification Envelope: Compare fragmentation results with the desired range for crusher compatibility.

- Sphericity Lines: Assess shape uniformity to ensure good material flow.

- Boulder Identification and Oversize Control

- Utilize WipFrag’s Boulder Count tool to detect and quantify oversize particles.

- Identify areas where secondary breakage or blasting adjustments are needed.

- Continuous Improvement and Optimizaton

- Compare multiple blasts using WipFrag’s Merging Feature to track fragmentation trends.

- Adjust blasting parameters (e.g., burden, spacing, explosive charge) based on data insights.

- Improve fragmentation efficiency by reducing fines and oversized materials.

Conclusion

WipFrag is a powerful tool for Blasting QC, enabling operators to measure, analyze, and optimize fragmentation performance. By integrating WipFrag into the blasting workflow, mining professionals can achieve better consistency, reduce operational costs, and enhance overall efficiency.