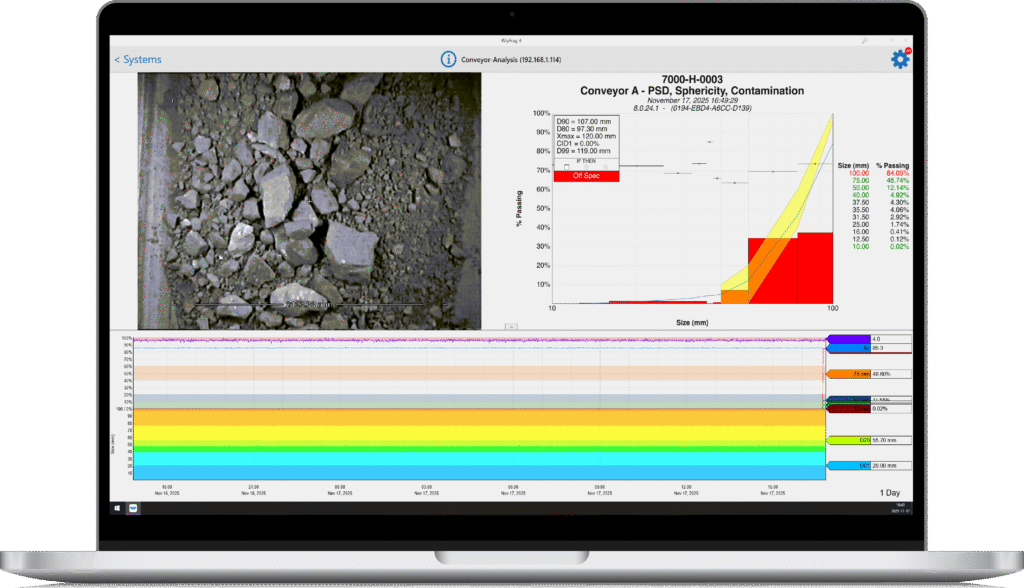

Real-time fragmentation and material quality measurement during haulage & dumping

Instantly measure fragmentation on the move

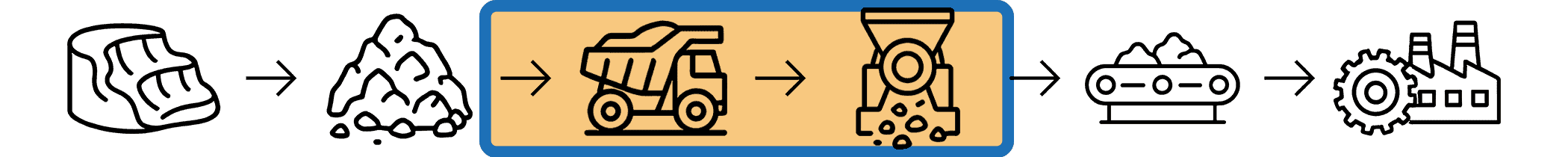

How Reflex Fits in the Value Chain

As your trucks, trams and railcars haul material from the blast site to the crusher, Reflex delivers real-time insight at this critical handoff point. This ensures that you:

- Detect oversize or problematic fragmentation early — before material is dumped into the crusher

- Monitor load quality in real time, reducing surprises in crusher feed

- Validate and tune blast performance via consistent feedback from every truck load

- Support ore-type control and contamination detection via colour metrics

- Optimize hauling and loading efficiency based on fragmentation trends

- Automate process decisions — e.g. alarms, diversions, or data-triggered events — via PLC/SCADA integration

What Reflex Does

Reflex continuously analyses rock fragmentation inside vehicle loads such as haul trucks, scoop trams, rail cars and more to provide your process with critical data and control.

Reflex provides:

- Full particle size distribution (PSD) analysis updated load-by-load

- Shape and uniformity metrics for fragmentation quality

- Oversize detection with automated triggers for alarms or diversion logic

- Trend tracking to identify consistency, drift, or variance over time or dig location

- Colour-based detection to monitor ore type changes or contamination

- Real-time data integration with control systems (Modbus TCP / OPC UA) for automated responses

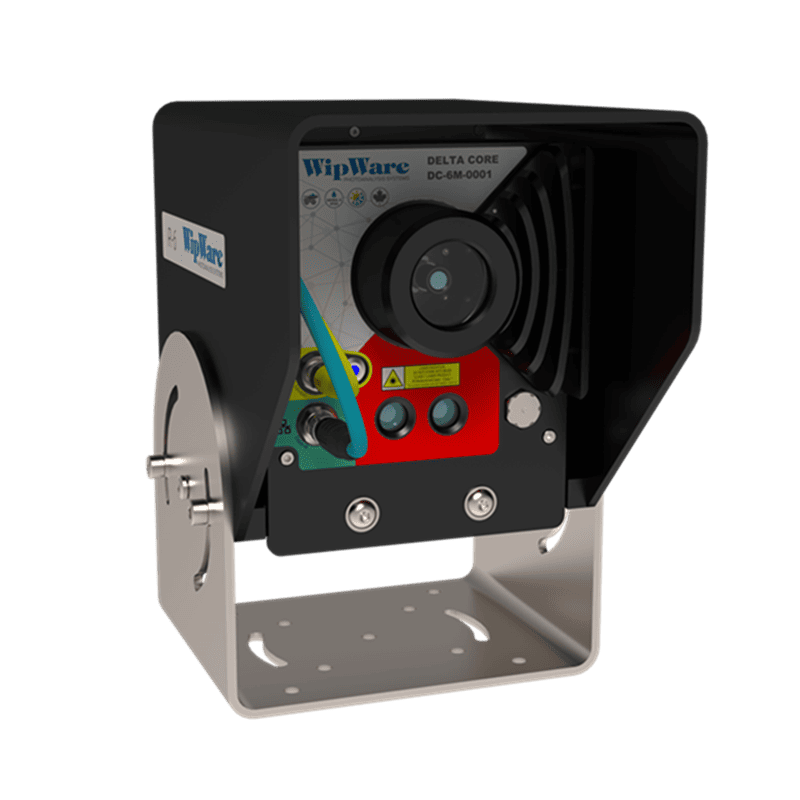

- Rugged and autonomous operation 24/7, even in extreme environments

Reflex Options: Choose the Capability You Need

Reflex is available in two configurations, both built on the same hardware platform. Start with the essentials — or unlock full analysis capabilities from day one. Upgrading between versions requires no hardware changes.

Reflex Basic

A streamlined solution for real-time detection and simple process control; ideal for:

- Oversize detection

- Colour/contamination analysis

- Load validation

Perfect when you need fast, reliable alerts without full granulometry.

Reflex Complete

Everything in Basic, plus advanced analytics for full material insight:

- Full particle size distribution (PSD)

- Up to 25 user-defined size classes

- Shape distribution and dilution reporting

Designed for operations that need comprehensive, high-accuracy monitoring.

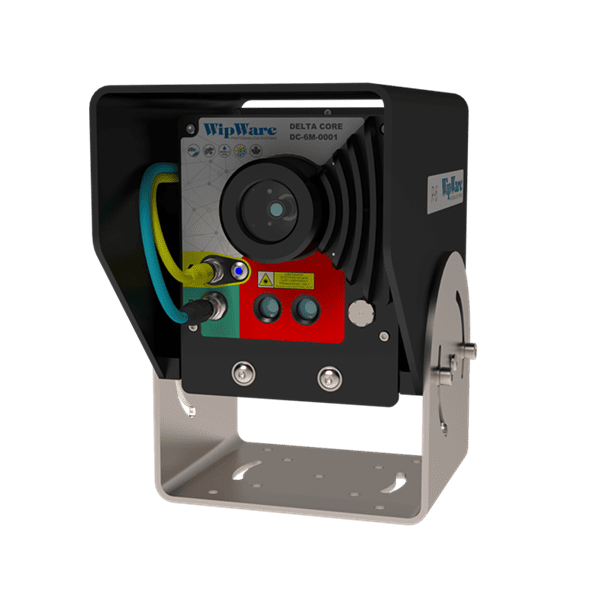

Our analysis systems are designed to be user-friendly, small footprint, economical, and easy to install.

Proven Performance

See how our customers are using Reflex

20% increase in crusher productivity

Automated fragmentation photoanalysis is being used at our Ravena quarry for continuous drill, blast and primary crusher optimization. WipWare’s Reflex system has enabled us to evaluate drill and blast performance, leading to a 20% increase in crusher productivity, and a 12% reduction in crushed product cost, with no change in drill and blast cost.

Read about using Reflex to measure blast fragmentation and optimize crusher feed

Typical Applications

- Blast-to-crusher fragmentation feedback for optimizing future blasts

- Quality control on muck-haul trucks before dumping to prevent over-sized feed

- On-the-fly ore type monitoring and contamination detection

- Load-by-load fragmentation reporting for performance benchmarking

- Automated process control via integration with plant SCADA or fleet systems

Get Started with Reflex

Reflex systems are installed and commissioned by our specialist team and can be tailored for your vehicle type and site conditions.

Contact us today for a detailed quotation or to schedule a demo.