Fragmentation analysis is a critical driver of mine performance, profitability, and sustainability. Accurate measurement and control of rock fragmentation from drill and blast to crushing and milling directly influence throughput, energy consumption, equipment wear, and operating costs.

WipWare’s fragmentation analysis solutions use advanced image processing and AI-driven technologies to deliver high-quality, real-time particle size distribution (PSD) data. This enables mining operations to optimize processes across the entire value chain, from pit to plant, while maximizing life-of-mine value.

End-to-End Fragmentation Analysis: From Drill to Mill

WipWare provides a fully integrated fragmentation monitoring ecosystem, offering consistent, accurate PSD measurement at every stage of material handling. By connecting blasting performance with crushing and processing outcomes, operations gain unmatched visibility and control over their production system.

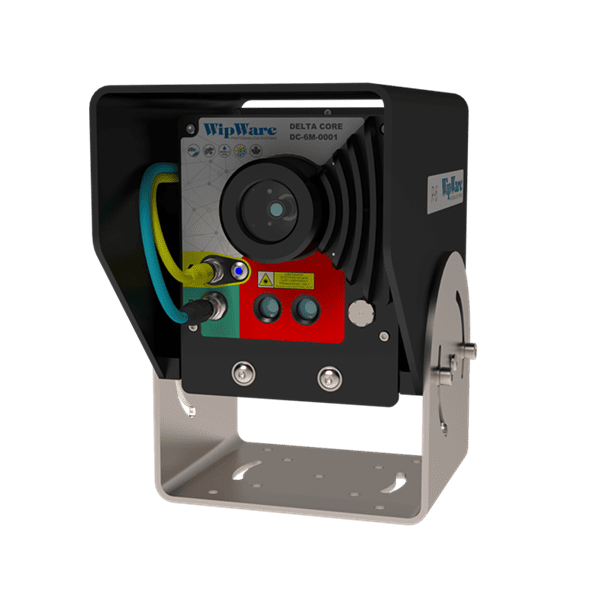

Online Conveyor Belt Fragmentation Measurement – Solo 6

Solo 6 delivers continuous, online particle size distribution analysis for conveyor belts across the comminution circuit, including:

- Primary crushers

- Secondary and tertiary crushers

- Pebble crushers

- Screen decks

With real-time fragmentation data at any conveyor belt location, Solo 6 allows operators to quickly detect changes in feed size, optimize crusher settings, and maintain consistent plant performance.

Real-Time Pit-to-Plant Fragmentation Control – Reflex 6

Reflex 6 measures the particle size distribution of post-blasted rock as it is delivered to the primary crusher, Bin and Stockpile. This real-time monitoring capability ensures effective management of the critical transition from pit to plant, reducing variability, minimizing crusher blockages, and improving overall throughput.

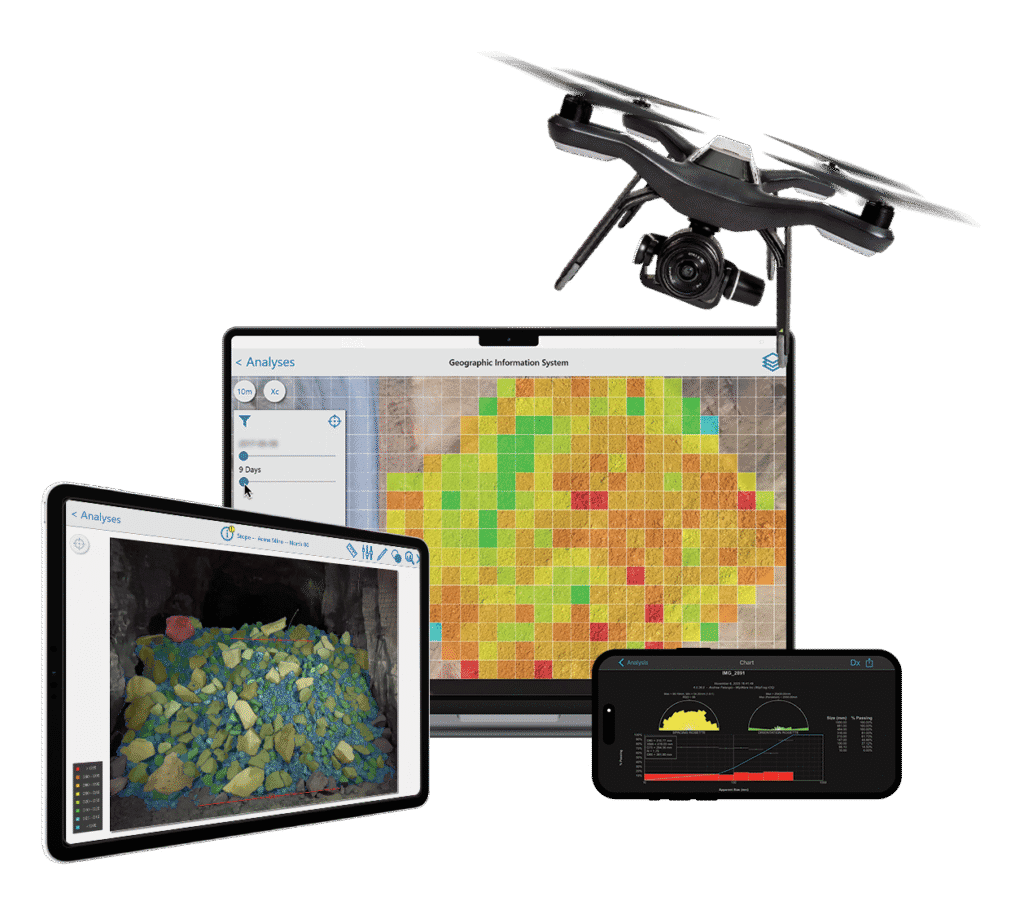

In-Pit Fragmentation Analysis – WipFrag 4

WipFrag is the standard industry solution for post-blast fragmentation analysis in open pit and underground mines. It enables engineers to accurately quantify particle size using:

- Mobile phones

- PCs

- Drones (UAVs)

WipFrag provides fast, reliable fragmentation assessments directly in the pit, supporting blast design validation, performance benchmarking, and continuous improvement.

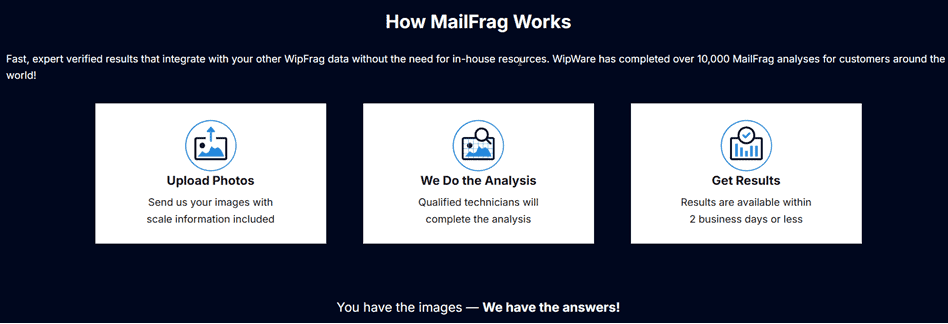

Outsourced Fragmentation Analysis – MailFrag

MailFrag is a service that offers a simple and efficient solution for teams who like to get results with the help of WipWare in-house image processing specialists. By leveraging WipWare’s experienced analysts, MailFrag delivers professional fragmentation size distribution reports, allowing operations to focus on decision-making rather than data processing.

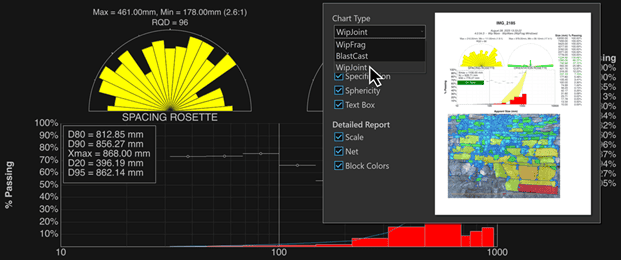

AI-Based Geotechnical Analysis – WipJoint

WipJoint, a powerful feature within WipFrag, extends value beyond fragmentation by applying AI imaging technologies to geotechnical analysis. It supports the identification and characterization of rock mass structures, joints, and discontinuities, contributing to safer blast design and improved rock mass understanding.

Blast Fragmentation Simulation – BlastCast (Swebrec Model)

BlastCast enables predictive fragmentation modeling using the Swebrec distribution, allowing engineers to simulate blast outcomes before execution. This supports:

- Optimization of blast design

- Reduction of oversize and fines

- Alignment of fragmentation with plant requirements

Simulation-driven planning leads to improved consistency, lower costs, and better downstream performance.

Why Fragmentation Analysis Is Critical to Mine Profitability

By integrating measurement, analysis, and simulation, WipWare’s fragmentation solutions transform raw images into actionable intelligence. This holistic approach improves safety, increases productivity, reduces energy consumption, and aligns pit-to-plant performance.

Fragmentation analysis doesn’t just measure rock; it drives smarter mining decisions across the entire life of mine.