We’ve put together some photoanalysis systems FAQs based on questions from our customers.

WipWare Image Analysis Systems produce real-time 24/7 results that allow personnel to identify, evaluate, and optimize troublesome areas of their process while maintaining production.

Our systems are installed in many different applications around the world. These applications vary from analyzing wood chips to detecting oversize material or contamination in diamond mines. The applications are endless.

From Mine to Mill

The term Mine to Mill highlights the importance of fragmentation data on both the blasting and processing end of operations. This term applies well to WipWare line of products from the muckpile after a blast to analyzing material on the conveyor.

Mine-to-mill technology takes the entire system into account, from the blasting process to the comminution circuit. This optimization provides a complete fragmentation and size reduction solution to maximize benefit.

Software de análise de imagem WipFrag

WipWare’s WipFrag 4 Image Analysis Software effectively analyzes data from a recent blast and produces results of the blast material on-site in minutes.

Reflex Vehicle Analysis System

From there, as the trucks haul the material to the primary crusher, you can detect oversize material or contamination and divert the material accordingly.

Once at the primary crusher, our Reflex systems can detect oversize material, contamination or give full particle size distribution analysis as the material is dumped.

Solo Conveyor Analysis System

After the material has gone through this process our systems can continue to analyze the material on the conveyor belt.

At this stage, you can determine what is the most important information you want to retrieve: detect oversize, divert material, identify contaminated material or receive full Particle Size Distribution data 24/7 in real-time.

Now, here’s the cool part: our WipFrag software is also the HMI (Human to Machine Interface) for our systems. Not only can you use our software separately to analyze your blast material, but the same software is also used to analyze your material all along its journey from Mine to Mill.

Many potential customers ask this very question about the benefits of WipWare products. Well, here’s the answer.

WipWare offers industry-leading photoanalysis technology for accurate, real-time fragmentation assessment, optimizing blasting, crushing, and grinding operations. With features like deep learning, auto-scaling, GIS compatibility, and orthomosaic analysis, WipWare ensures precise measurement and continuous improvement. The software’s specification envelope, histogram reporting, and boulder counting enhance decision-making, reducing downtime and costs. Additionally, WipWare provides flexible pricing, cross-shipping warranties, and expert support, making it the top choice for efficient mining and aggregate operations.

Furthermore, our online Systems provide data to the customer 24/7 to identify troublesome areas of your process from Mine2mill.

In conclusion, our Só Basic or Complete, Reflexo Basic or Complete and WipFrag software can drastically lower energy, and maintenance costs, as-well as cut equipment downtime and aid in quality control.

WipWare usa lasers de detecção de profundidade de cinto para detectar ambos

A) Cintos vazios, como nos modelos Solo anteriores

B) A profundidade do material na correia transportadora

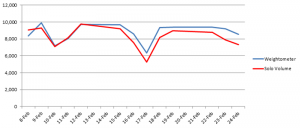

When you tie the material depth information with the conveyor belt speed and your belt weightometer reading, you are able to extract the specific gravity of the material passing. Having the specific gravity information will allow you to determine whether the material passing is waste or ore-bearing material.

Em testes preliminares em uma operação de calcário, WipWare foi capaz de alcançar a correlação 94% entre os cálculos volumétricos e as leituras do medidor de peso.

Uma operação pode usar essas informações para evitar que o material residual entre no processo de britagem, economizando quantias significativas de dinheiro em custos de manutenção e energia.

Volumetrics users have the added benefit of receiving accurate particle sizing results as well as another new feature allowing you to detect contamination.

Com tamanho, formato, volume e dados de detecção de contaminação sendo transmitidos continuamente em tempo real, as tecnologias automatizadas do WipWare estão fornecendo três vezes mais métricas de dados precisas do que os concorrentes.

Na WipWare, muitas vezes nos apresentamos como fornecedores de tecnologia de mineração e agregados, já que essas duas indústrias compõem a maior parte de nossos negócios. A beleza das tecnologias de fotoanálise é que, com uma imagem adequada, nossos produtos podem analisar qualquer coisa, desde material mícron até planetas. Todos nós sabemos que o dimensionamento automatizado de partículas é uma parte crucial da indústria de mineração e agregados, mas como você verá, o tamanho do material não é importante apenas para as rochas. Aqui estão alguns dos aplicativos interessantes com os quais tivemos o prazer de trabalhar:

Mars Curiosity Rover: There may not be any mining on Mars (that we know of), but the Curiosity rover is taking pictures that are being analyzed for oversized obstacle detection. What a great way to identify and steer clear of obstacles and keep Curiosity roaming.

Ovos mexidos. That’s right, I said scrambled eggs. A food supplier from the US contacted us looking to optimize the fluffiness and fragmentation of the scrambled eggs they use. I’ll never look at scrambled eggs the same way ever again.

Kimberlito processado: Getting out of our chef’s apron and putting our hard hats back on, we have been working very closely with multiple diamond companies around the world to accurately analyze the process kimberlite material on their conveyor belts. What’s so incredible about this application? Well, it’s pretty normal, except for the fact that the material ranges from as low as 1.2mm (0.0472440″ for our Imperial friends). Once again, if a suitable image can be captured, WipWare can analyze it.

…And of course, we work with hundreds of applications that deal with broken screen detections, contamination, quality control procedures, pre- and post- crusher optimization and SAG mill throughput applications.

Both Delta (Solo 6 and Reflex 6) and WipFrag produce a percentage passing curve visible after each virtual sieve analysis. It also saves the data to a CSV (comma-separated values) file. Each sieve analysis produces a new line in the CSV file that represents the results from the sieve.

Este arquivo CSV contém:

– Timestamp (Year/Month/Day/Hour/Minute/Second)

– D-values (XX% passed the specified size – Ex. 90% of the material passes 13.87 inches[352.30mm])

– User specified size classes (% passing or retained at the specified size)

– Block (amount of particle detected)

– Min, Max, Mean, St. Dev, Mode

– Sphericity (The shape of the material – 0=Linear Objects 1=Perfectly Round)

– Coverage (How much of the image is used)

– Calibration Values (b, Xmax, X50, Xc and n)

– EDP values (Edge Detection Values)

– Calibration factors

– System info (CPU temp, Board temp, Voltage checks)

– System uptime

– Camera setting at the time of the image.

– Modbus and OPC poll rate

– Vehicle Identification Information (Reflex Only)

Delta (Solo 6 and Reflex 6) can e-mail these CSV files automatically as well as an average of the entire day on one passing curve. It also has a trending graph in the lower section of the software interface which trends the data for the current day.

Além disso, a Delta tem a capacidade de produzir as informações de análise usando uma conexão Modbus ou OPC para passar informações para seu historiador, PLC ou HMI.

A única manutenção regular necessária para nossos sistemas é garantir que as lentes e as luzes estejam limpas com o mínimo de poeira / sujeira possível.

A frequência com que o sistema precisará ser limpo dependerá do ambiente em que opera:

AMBIENTE / FREQUÊNCIA

Muito empoeirado 1-3 semanas

Poeira moderada 2-6 semanas

Pouca ou nenhuma poeira 4-8 semanas

Método 1: mangueira de água

The first method is the most common. Using a water hose, simply spray down the system ensuring the lens is clean and free of any noticeable dust or dirt. If possible, use a squeegee to remove any droplets that may remain on the lens. Doing this helps prevent dust from collecting in the droplets that remain which could leave deposits on the lens that interfere with image capture. Since our systems are completely waterproof this method is usually the easiest and most effective way to clean the lens. It can also be done without having to shut down the conveyor belt.

Método 2: limpe um pano úmido / toalha de papel

Outra opção é usar um pano úmido limpo ou toalha de papel com água ou Windex. Usar um pano de microfibra limpo seria o ideal, mas pode ser difícil de encontrar em minas. Tente não fazer muita pressão ao limpar a lente, a poeira acumulada pode deixar arranhões na lente se muita pressão for aplicada. Nota: Em temperaturas abaixo de zero, evite usar água ou Windex, pois congela na lente e causa qualidade de imagem inadequada. Recomendamos o uso de lavador de pára-brisa padrão classificado para a temperatura correta abaixo de zero.

Método 3: ar comprimido

It’s also acceptable to use compressed air from a can or hose to dust off our systems. This method works well but will kick up a lot more dust than the liquid methods. We recommend using a dust mask when using compressed air to clean off out systems.

A resposta simples é sim.

The computer can store up to 1000MB worth of images without any issues. Once beyond this point the hard drive could start having problems accessing the image folder causing the computer to run slower than normal, so the oldest images are overwritten automatically.

Nota: Todos os dados de tamanho de partícula são mantidos em um arquivo CSV que é um tamanho muito menor e permite que você armazene dados em uma linha do tempo mais longa.

A maioria dos nossos sistemas usa uma câmera de 1,2 MP e as imagens têm em média 180 KB cada, portanto, 1000 MB de armazenamento podem acomodar aproximadamente 5600 imagens.

Running 24 hours per day the system can roughly save the following number of images:

Se você estiver tirando 1 imagem a cada 20 segundos, terá 4.320 imagens por dia. ~ 31,2 horas

Se você estiver tirando 2 imagens a cada 20 segundos, terá 8.640 imagens por dia. ~ 15,5 horas

Se você estiver tirando 3 imagens a cada 20 segundos, terá 12.960 imagens por dia. ~ 10,3 horas

To calibrate, or not to calibrate; that is the question. And it’s an important question to ask prior to installing your online bulk material analysis system, regardless of the industry you’re in. Let’s help you figure out why calibration may or may not be your best bet, and whether you will see value in calibrating your system.

Uma das deficiências da tecnologia de análise de fragmentação de rocha baseada em imagens é a incapacidade de analisar o material subjacente em uma esteira transportadora. Portanto, em circunstâncias normais, sem calibração, o material fino é normalmente sub-representado ao usar a análise de imagem. A mesma coisa pode ser dita para a análise de fragmentação da explosão, mas irei abordar isso um pouco mais adiante no artigo.

Se as tecnologias de análise de fotos representam o material na camada superior e subrepresentam o material subjacente, uma operação pode compensar essa deficiência calibrando. (Para obter o guia prático sobre calibração, verifique este link).

The way I see it, without sounding too much like a broken record, calibrated photo analysis technologies take the best of both worlds: Quantity and quality.

Take the following scenario as an example: Company ABC wants to adjust the SAG feed based on particle size analysis. By doing so, they need to know when to draw fine material from the stockpile and when to draw coarser material. Calibration allows for the proper “mix” of bulk material in order to optimize the process.

The Swebrec and Rosin-Rammler functions are great for adjusting the distribution curve to accurately compensate for fine material… But what if you are looking strictly at the coarse sizes, say, for oversize detection?

If this is the case, you may want to reconsider the calibration process.

Allow me to explain:

A calibrated system is making certain assumptions about material underneath the top layer and may even bias your coarse material fractions when trying to adjust the distribution curve. So, if you are planning on having a conveyor belt shut down if it detects material over x size, you may want to reconsider taking the chance of biasing your results. Instead, an uncalibrated system is going to get you very useful data that will allow you to stop/start/act on out-of-spec readings and optimize your process.

What are other reasons why clients don’t calibrate?

Quando o material é muito grande, é muito mais difícil fazer a amostragem manual do material e isso pode ter um custo proibitivo. Esse problema surge com mais frequência no final da detonação da aplicação, onde a otimização da detonação depende muito da detecção de mudanças relativas no tamanho do material.

Para análise pós-triturador, alguns clientes detectam desgaste do revestimento por aumentos relativos no tamanho do material, tornando a calibração desnecessária.

Em resumo, a calibração certamente tem seus usos dentro das indústrias de mineração e agregados e, mais especificamente, quando tamanhos de materiais mais finos são uma parte necessária do dilema; entretanto, os sistemas não calibrados ainda são muito úteis na otimização do seu processo e no rastreamento de mudanças relativas.

WipWare Inc. provides a one-year limited warranty on all products, including components and software. To offer customers peace of mind, WipWare also offers an annual service contract, which includes exclusive technician service rates, monthly check-ins, extended system warranties, and more.

With the purchase of any WipWare photoanalysis product, the warranty covers cross-shipping for any defective product under the WipWare Limited Warranty, ensuring minimal downtime for customers.

Para obter os detalhes completos da garantia limitada WipWare, consulte aqui.

WipWare goes above and beyond to ensure that not only customers, but any individual or company who may show interest in a WipWare product has the utmost training and confidence when it comes to utilizing our extensive line of photoanalysis systems. WipWare offers free training to individuals, companies, colleges, and universities interested in learning about our products. We recently conducted on-campus workshops for mining students at Queen’s University (Kingston), Laurentian University (Sudbury), and ÉTS University (Montreal). In addition to in-person sessions, we provide virtual training and have a library of training videos available for easy access.

For more information about WipWare training please contact support@wipware.com

For more information about our systems, please visit our YouTube channel.