How Low Can You Go?

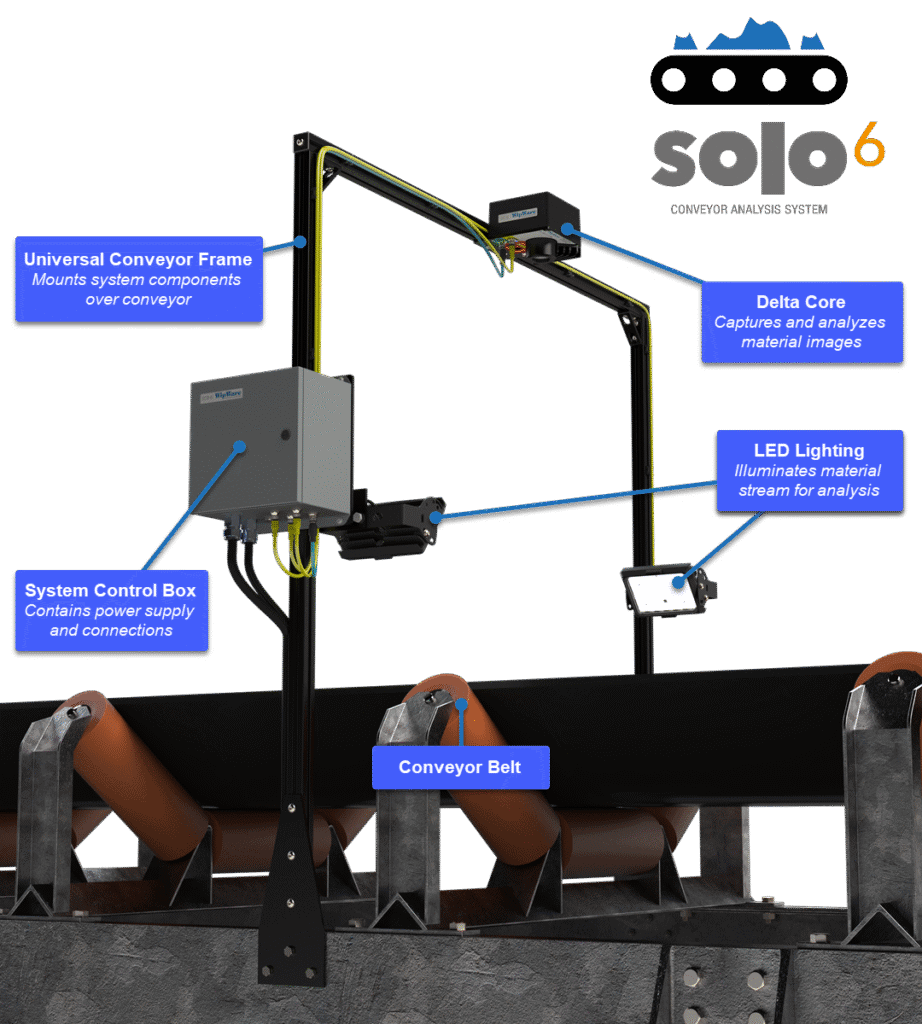

One of the most common questions we receive is, “How small can you analyze?” The answer depends on multiple factors, but with the right imaging, WipWare’s systems can measure down to micron levels. However, when analyzing material on conveyor belts, additional considerations impact the minimum particle size that can be accurately measured.

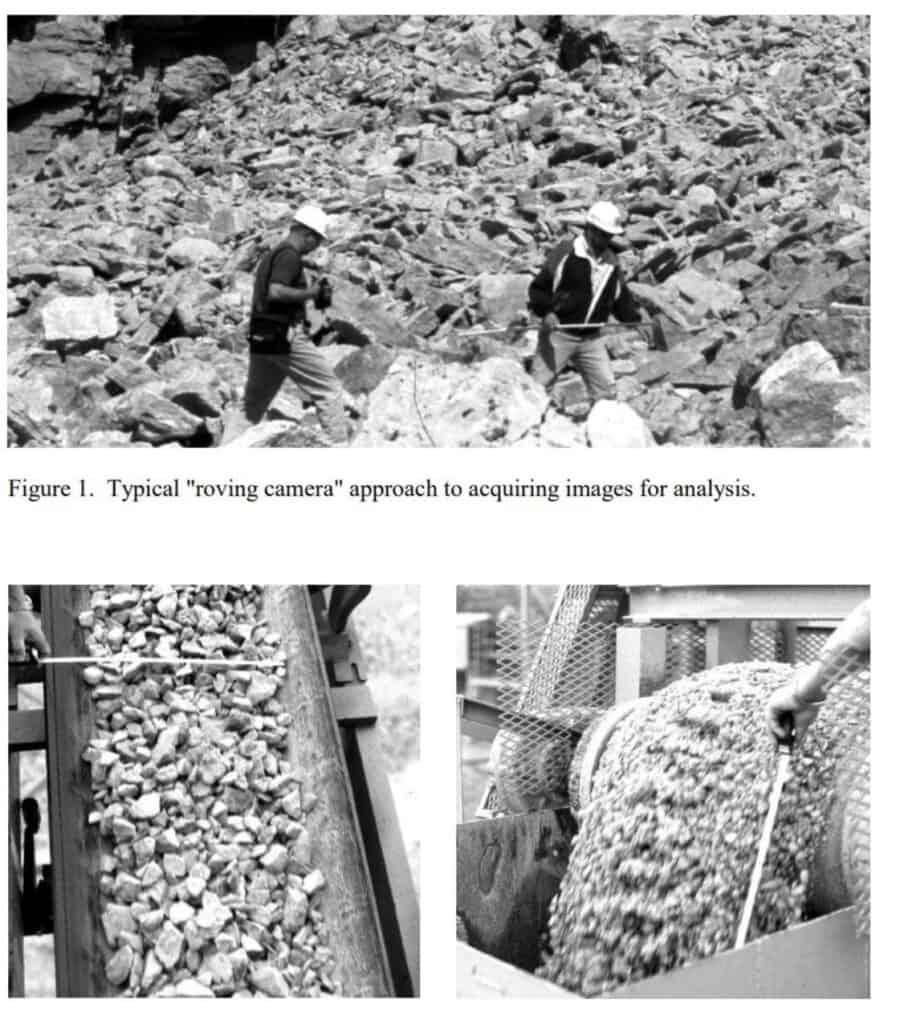

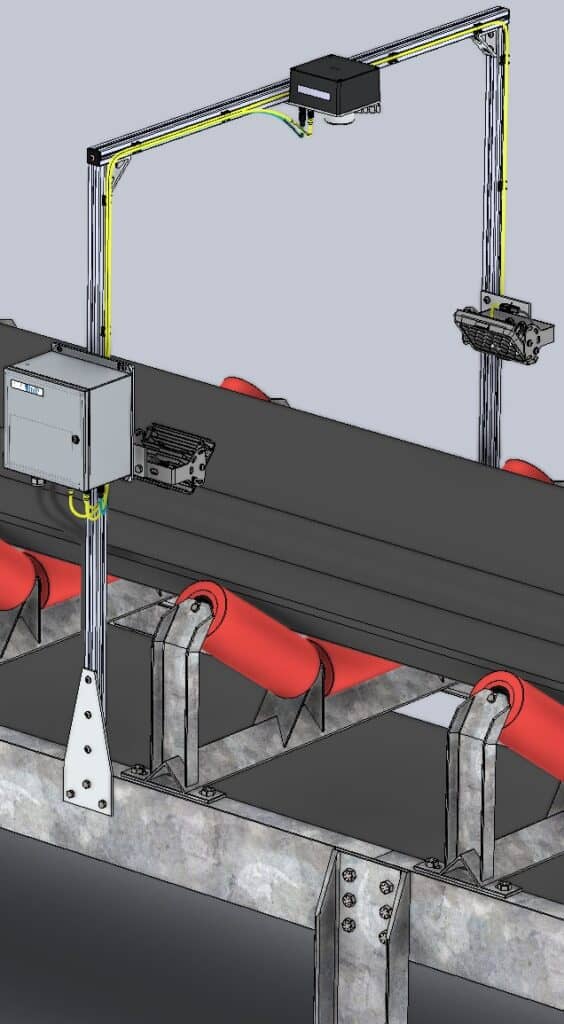

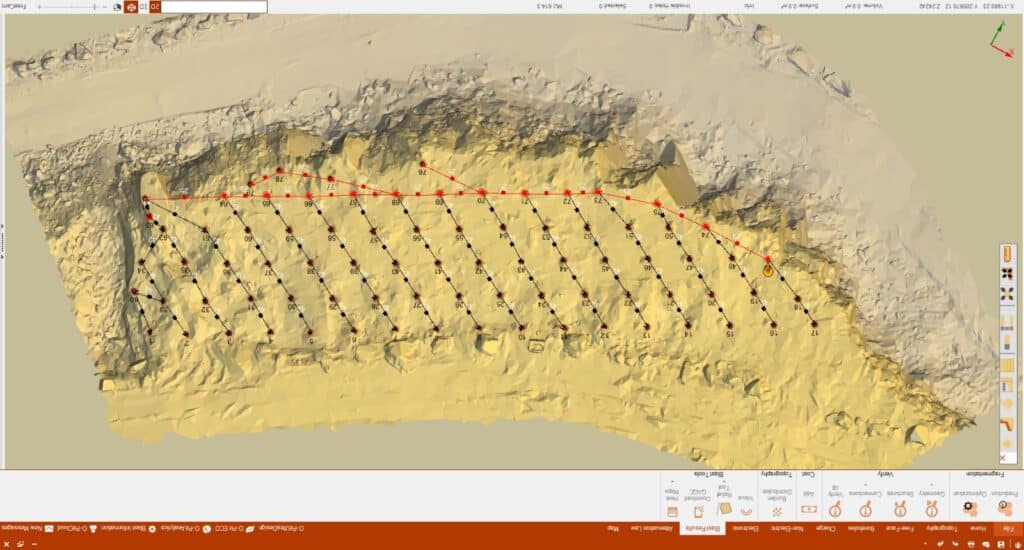

Over the years, we’ve worked with a vast range of conveyor belt applications from highly quality-controlled 10-inch belts to massive run-of-mine conveyors that are several metres wide as is normally found in global copper, iron ore mine operations. Our fully adjustable frames are customized before shipping to ensure seamless integration into your operation.

Key Considerations for Conveyor Belt Analysis

When it comes to analyzing material on conveyor belts, a few fundamental factors come into play:

- Fixed Camera Position – The camera is mounted at a consistent distance from the belt, usually within a metre or so (a few feet).

- Controlled Lighting – Conveyor belt environments generally offer stable lighting conditions, improving image accuracy.

- Material Spread – The material stream typically covers a predictable portion of the belt rather than the entire conveyor surface, allowing the camera to focus specifically on the material.

- Controlled Flow – Conveyed material has a known source and destination and moves at a controlled speed and direction, making variables easier to control.

With these stable conditions, WipWare’s systems can precisely determine the size ranges they analyze for each application.

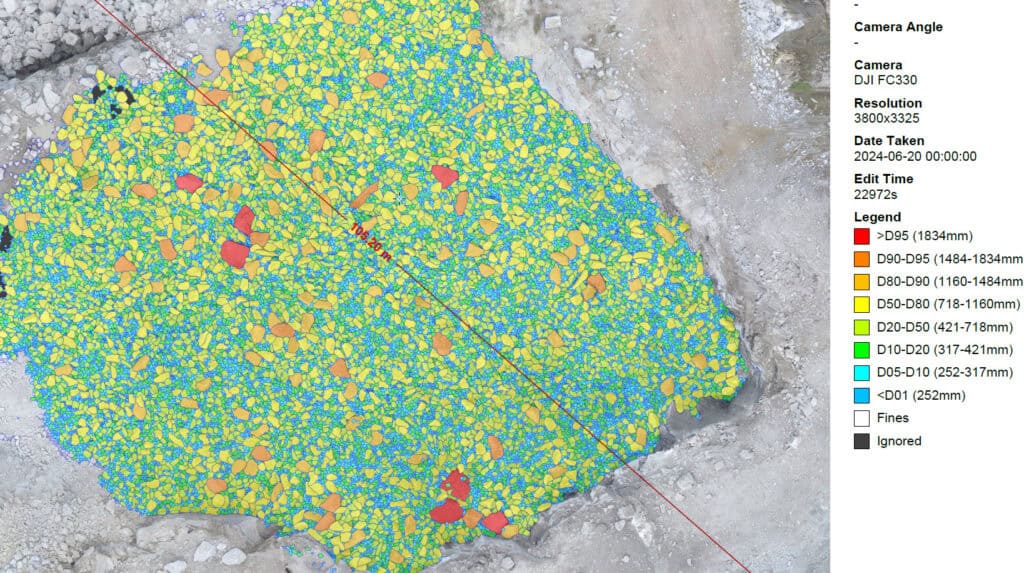

Real-World Examples

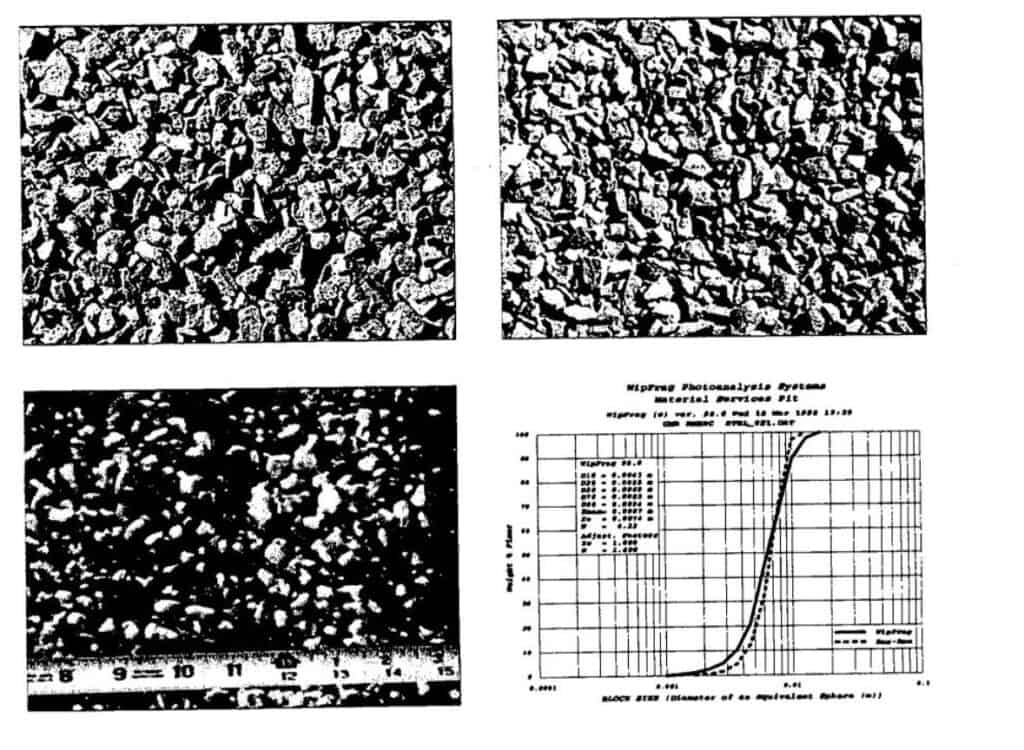

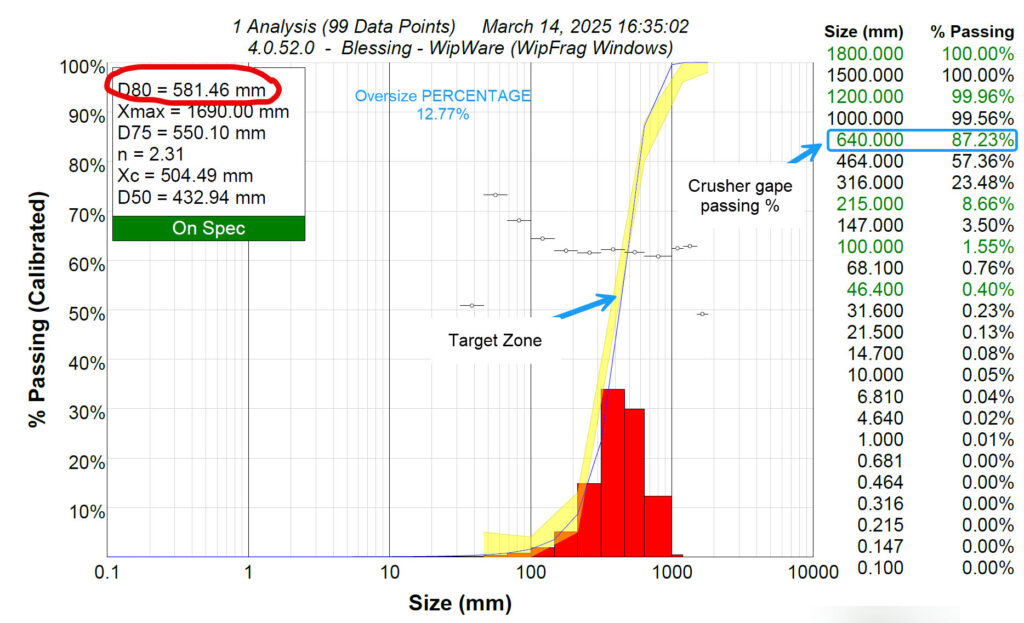

Let’s explore two real-world examples using WipWare’s Só system:

| Empresa | ABC Company | XYZ Company |

|---|---|---|

| Material Type | Copper | Gold |

| Conveyor Dimensions | 3 metres / 10 feet | 1.2 metres / 4 feet |

| Analysis Location | Primary crusher output | SAG mill feed |

| Detectable Sizes | 7.14 mm – 609.6 mm 0.2812 in (~#3) – 24 in | 2.86 mm – 243.84 mm 0.1125 in (~#7) – 9.6 in |

From the comparison table above, we see that ABC Company’s larger conveyor widths require the particle sizing system to be mounted higher to capture the full material spread. This setup means the system focuses more on coarser size fractions than fines – which is good: If a 3-metre belt is in use, and the material is raw primary crusher output, it’s unlikely that the material is 100% fines.

In contrast, Company XYZ deals with crushed and pre-screened materials, meaning the belt carries smaller particles. Since the conveyor is smaller in width, the system mounting height is closer to the material and can therefore analyze smaller size fractions.

Note: These are real-world examples with their own unique challenges which affect the detectable size range and goals which determine the focus of data collection. Your own application could have very different detectable size ranges depending on similar factors at your operation.

Expanding the Size Range: What are the options?

If you need to adjust the minimum or maximum detectable particle size, consider the following:

- Calibrate for Unseen Fines – Using sieve data and manual belt cuts to measure unseen and unresolvable fines and calibrate the system output accordingly. This is good for known and predictable material streams.

- Reduce the Field of View – Narrowing the system’s focus by adjusting the position or changing the type of lens used to view a smaller area. This in turn may limit the ability to capture coarser sizes.

- Increase Camera Locations – Using multiple cameras on the same material stream to capture different ranges of material, ie. a “fines” camera and a “coarse” camera.

- Tailored Solutions for Your Operation – The technology itself can change for your specific needs, such as increasing the camera resolution or changing the mounting solution.

If you’re wondering how effective a WipWare analysis system would be for your operation, Contate-Nos! Our technologies have helped mining operations worldwide achieve better process control.

Have a unique application? We love a challenge — send us the details, and we’ll be happy to assist!