WipWare’s automated fragmentation analysis systems help mining and aggregate operations measure, monitor, and optimize material size from blast to mill. From initial blasting to conveyor-fed processing, our solutions turn complex particle analysis into actionable insights that improve productivity, safety, and efficiency. Because you can’t manage what you can’t measure!

Fragmentation Across the Value Chain

Good fragmentation is critical at every stage of mining operations. Variability affects shovel productivity, crusher throughput, conveyor flow, and downstream process efficiency. WipWare’s digital particle size analysis systems provide the data needed to reduce bottlenecks, lower operational costs, and improve equipment life.

Where our products fit:

Blast & Muckpile

Plan better blasts, benchmark fragmentation, reduce oversize

Haulage & Transfer

Monitor vehicle loads, detect anomalies, improve haul efficiency

Crushing & Conveying

Optimize crusher feeds, reduce process issues downstream

A single ecosystem, spanning the full value chain, designed to deliver consistent, actionable fragmentation insights.

Technology Platform

At the core of our products is a real-time, image-based fragmentation analysis system:

- Capture high resolution images of material at any point in the operation

- Automatically delineate particles and calculate size distributions

- Analyze trends across multiple sites and equipment

- Integrate with fleet management, SCADA, and reporting systems

- Scale from single measurement points to fully automated, continuous monitoring

This shared technology platform ensures consistent data quality, accurate analytics, and actionable insights across your operation.

The WipWare Ecosystem

Three products, one workflow:

ब्लास्ट मॉडलिंग, मकपाइल विश्लेषण, और परिचालन बेंचमार्किंग के लिए सॉफ्टवेयर

वास्तविक समय निगरानी के लिए वाहन भार का स्वचालित मापन

क्रशर और फीड अनुकूलन के लिए कन्वेयर-आधारित खंडन विश्लेषण

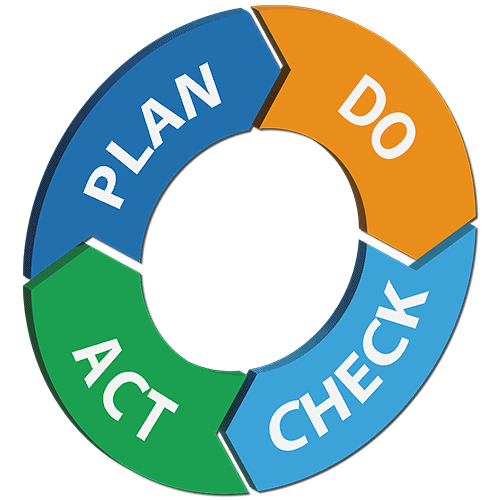

Continuous Improvement Loop

Mining operations thrive on iterative improvements. WipWare’s systems allow operators to:

- Measure fragmentation across the operation

- Analyze trends and variability with precision

- Adjust blasting or processing parameters

- Verify results and close the optimization loop

The result: continuous improvement from blast to mill, supported by data you can trust.

Proven Impact

Operators using WipWare’s automated fragmentation analysis systems have reported:

- Reduced crusher downtime and interruptions

- Improved throughput consistency

- Lower frequency of oversize material

- Better fragmentation predictability across benches and ore zones

Speak with a specialist today to see which solutions fit your operational needs.