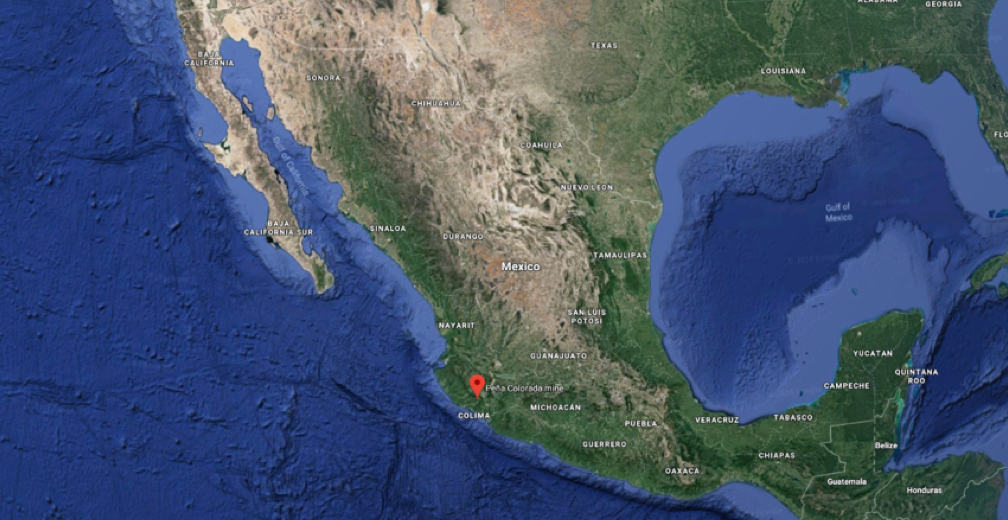

Our WipWare Technician, Thomas de Sousa, travelled to Pena Colorada in Mexico January 20-24th. The trip consisted of inspecting the installation and commissioning of a 2-Camera Momentum 5 Particle Size Analysis System. Getting a much enjoyed break from our Ontario winter, he met with the Pena Colorada Metallurgical team. Tommy received a warm welcome from the Pena Colorada team. Everyone was ready to get down to work.

Previous Installation Inspection

One advantage to visiting existing customers is the opportunity to review previously installed systems. Sometimes, during these visits, our customers can inform our specialists of any issues they’ve encountered. With this information, our technical specialists can investigate the issue while on-site and help determine what’s happening.

If a system is not functioning properly, our team will take the time to inspect and fix on-site if possible. So, when Tommy arrived on-site, the Momentum installations were still in progress. Tommy used this time to investigate the software and connection issue that was occurring with the previous installed Solo 5 system. The team decided that Tommy would return home with the camera head to fix any issues with the camera.

New Momentum 5 Commissioning

Once Tommy had completed the inspection of the Solo 5 system, he proceeded to commission the 2-camera Momentum 5 system. The first step in commissioning this system was inspecting the two preliminary installations.

After the initial inspection, they erected the Momentum frames. All electrical and network cables were inspected and the installation was good. Our technical specialist always appreciates the preliminary work that our customers do prior to their arrival.

The third step was to add the camera assembly to each frame and calibrate the system. The installation and calibrations were successfully completed and it was time to call it a a day.

The following day, after commissioning the system, our technical specialist provided training for the team before departing and heading back to Canada.

The Momentum 5 system is now collecting Real-time particle size telemetry on two conveyor belts.

“Efficiency and productivity for our beneficiation process: The WipFrag Momentum 5 System® technology from WipWare Inc. allows us to measure, monitor and control, in real time, the distribution of size, shape, uniformity and volume of iron ore that feeds autogenous mill. Knowing the magnitude of the impact of the different size fractions of ore fed, improves the performance of autogenous grinding from the breaker, increasing energy efficiency in mills and the productivity of the beneficiation process.” – From Pena Colorada

Thank you to the Pena Colorada team for all their assistance.