By: Mark Wagner

Every operation has a specification they need their material size to be within: Whether it’s ASTM specifications for aggregate operations, key performance indicators for crushers and SAGs, or blast metrics for explosives selection, these standards are crucial in streamlining an operation’s process.

For example: an operation in northern Quebec, Canada (if you are looking at a map of Quebec, chances are you are still not looking north enough… keep going… there you go) needed to ensure material size did not exceed 6″ in size coming out of the primary crusher, for a variety of reasons:

Energy required downstream to break down these large particles was significant

Maintenance issues in terms of damage caused by these oversize particles

Getting maintenance personnel on-site to deal with the aforementioned points was extremely costly

With the assistance of Xstrata Process Support (XPS) and a hydraulic toggle supplier, WipWare was able to not only identify when material was larger than 6″, but send signals to through a PLC that would automatically adjust the crusher mantle in order to bring the material size back in line. Just by reducing maintenance shutdowns to manually adjust the crusher setting, this operation was able to recoup the cost of the system within a year.

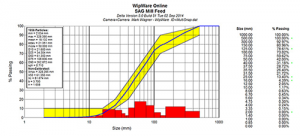

Even if your operation opts to manually adjust its process using WipWare’s systems as a guide, the benefits are widespread and significant. We’ve seen the timeline between liner replacements expanded drastically, and SAG feed optimized on-the-fly by utilizing online data as a standard.

…And for the folks who have dealt with paving specifications, all it takes is for a half mile of out-of-spec pavement to be pulled up to identify the importance of keeping material in between the goal posts.

Speaking more on the ground level of photoanalysis technology, envelopes can be created inside of WipFrag and Delta, so operators can identify out-of-spec material at a glance. Perhaps it’s a matter of notifying mining personnel, or shutting down a belt until liner maintenance is completed; regardless, having a tool that can help significantly in adhering to your operation’s standards can mean cost-savings, reduced downtime, and a more proactive approach to mining and milling.

Happy crushing!